A hydraulic press is a mechanical device that uses liquid as a working medium and utilizes Pascal’s law to transmit pressure and perform various process operations. Capable of generating tremendous pressure, it facilitates processes such as forming, pressing, stretching, and blanking metals, non-metallic materials, and composite materials, making it an indispensable piece of equipment in modern manufacturing. With the increasing adoption of smart manufacturing and green energy conservation concepts, the application of hydraulic presses is becoming increasingly widespread, playing a central role in everything from traditional metal forging to advanced composite material forming.

Table of content:

- working principle of hydraulic press

- structural components

- classification of hydraulic presses

- features and advantages of hydraulic press

- application areas

- development trends

- conclusion

1. Working Principle of Hydraulic Press

The basic principle of a hydraulic press is derived from Pascal’s law: In a confined liquid, a pressure change at any point is transmitted equally to all parts of the liquid. A hydraulic press uses a hydraulic pump to pressurize hydraulic oil and transfer it to a cylinder, pushing a piston to produce linear motion. This exerts tremendous pressure on the worktable, enabling the shaping or processing of workpieces.

In actual operation, the pressure, speed, and stroke of a hydraulic press can be adjusted according to process requirements. Modern hydraulic presses often utilize electro-hydraulic proportional control or servo control systems, enabling precise pressure and displacement control to meet the requirements of high-precision component production.

2. Structural Components of Hydraulic Press Machine

The main structure of a hydraulic press consists of the following components:

- Main unit: This includes the press body, cylinder, piston, and worktable, and is the primary structure for pressurized molding. The press body is typically welded or cast, requiring high rigidity and stability.

- Power system: This consists of a hydraulic pump, motor, oil tank, and valve block, providing stable hydraulic energy. Common pumps include vane pumps, plunger pumps, and gear pumps.

- Control system: This includes electrical and hydraulic control components, regulating pressure, speed, stroke, and implementing safety protection and automated operation. Advanced control systems enable the storage of multiple process parameters and intelligent production.

- Auxiliary devices: These include cooling systems, lubrication systems, safety protection devices, and quick mold change systems, ensuring the long-term, stable operation of the hydraulic press.

3. Classification of Hydraulic Presses

Hydraulic presses come in many varieties and can be categorized as follows based on various criteria:

1) By Structure

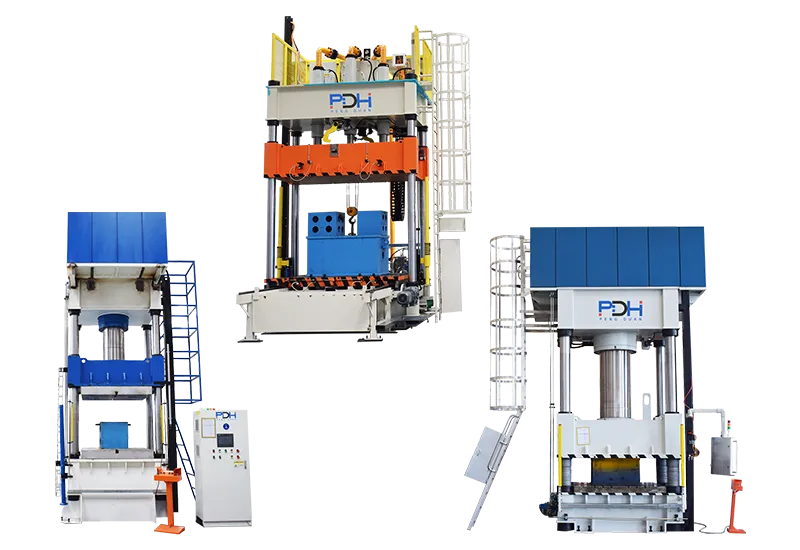

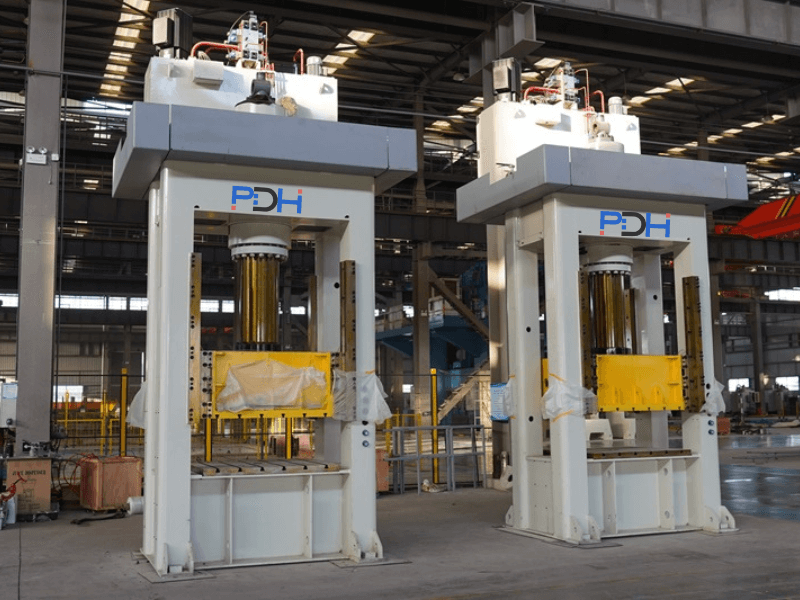

- Four-column hydraulic presses: Symmetrical in structure, low in cost, and widely applicable, they are the most common hydraulic press structure.

- Frame-type hydraulic presses: Excellent overall rigidity, suitable for large-tonnage and high-precision processes.

- Single-arm hydraulic presses: Simple in structure, commonly used for pressing, straightening, and assembling small parts.

2) By Function and Process

- Forging hydraulic presses: Used for metal forging and forming.

- Compression molding hydraulic presses: Suitable for molding composite materials, plastics, and rubber products.

- Deep Drawing hydraulic presses: Specialized for stretching and forming thin metal sheets, such as automotive panels.

- Powder molding hydraulic presses: Used for pressing materials such as powder metallurgy and ceramic powders.

3) By Control Method

- Conventional hydraulic presses: Controlled by a hydraulic valve block, they have a simple structure.

- Servo hydraulic presses: Driven by a servo motor, they are energy-efficient, efficient, and offer higher precision.

4. Features and Advantages of Hydraulic Press

- High and Uniform Pressure: Compared to mechanical presses, hydraulic presses provide higher pressing force and more uniform pressure distribution, making them suitable for forming large or complex parts.

- Wide Application: They can process a variety of materials, including metals, non-metals, and composite materials, meeting diverse process requirements.

- Flexible Operation: Pressure, speed, and stroke can be flexibly adjusted, providing strong adaptability.

- High Precision: Modern servo hydraulic presses achieve precise control of force and displacement through closed-loop control, ensuring consistent finished products.

- Energy Saving and Environmental Protection: The new generation of hydraulic presses utilizes an energy-saving hydraulic system, resulting in low energy consumption, low noise, and environmentally friendly operation.

- High Safety: Equipped with photoelectric protection, hydraulic overload protection, and an emergency stop system, operators are guaranteed safe.

5. Application Areas of Hydraulic Press Machines

Hydraulic presses are widely used in various sectors of the national economy:

- Metal Forming Industry: Used for stamping, bending, and stretching automotive panels, aerospace parts, rail transit accessories, etc.

- Composite Processing: Suitable for SMC/BMC composite molding processes, such as manhole covers, water tank panels, rail transit door panels, and bathroom fixtures.

- Powder Metallurgy and New Materials: Compress metal and ceramic powders to create high-performance components.

- Plastics and Rubber Products: Produce pallets, trash cans, pipe fittings, and automotive plastic parts.

- Building Materials Industry: Press cement components, building formwork, and wall materials.

- Consumer Goods Industry: Manufacture a variety of everyday products, including kitchenware, tableware, and decorative items.

6. Development Trends

With the advancement of Industry 4.0 and smart manufacturing, hydraulic presses are exhibiting the following development trends:

- Servoization and Intelligence: Utilizing servo motors and intelligent control systems, hydraulic presses achieve higher-precision pressure control and energy optimization.

- Automated Production Lines: Hydraulic presses are integrated with manipulators, mold libraries, and conveyor lines to achieve automated loading and unloading and fully automated pressing.

- Green and Energy-Saving: Utilizing new energy-saving hydraulic systems and environmentally friendly hydraulic oils reduces energy consumption and emissions.

- Customization and Multifunctionality: Developing specialized hydraulic presses to meet complex process requirements for industries such as aerospace, rail transit, and automotive lightweighting.

7. Conclusion

Hydraulic presses, as essential equipment in modern manufacturing, are widely used in a variety of industries, including metalworking, composite materials, powder metallurgy, plastics and rubber, thanks to their high pressure capability, wide applicability, and flexible operation. With the development of new materials and processes, the performance and functionality of hydraulic presses are continuously improving, moving towards high precision, energy efficiency, and intelligent features. They will play an even more important role in future industrial manufacturing.