Real Leading Hydraulic Press Machine

Manufacturer in China

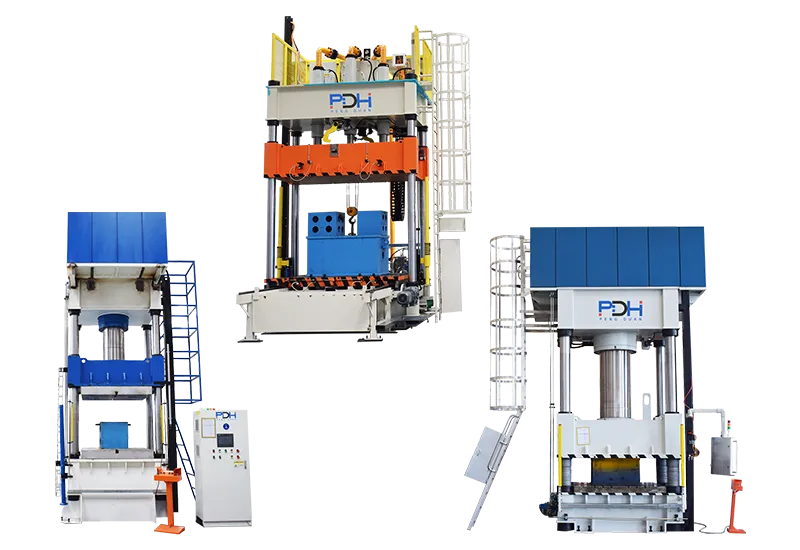

PDH’s main products: composite material molding presses, deep drawing presses, hydraulic forging presses, and various production lines.

Why Choose PDH

Processing Capabilities

PDH currently has more than 140 sets of advanced processing, testing and measuring equipment, including nine-axis machining center, large CNC gantry machining center, large heat treatment equipment, large lathe and others.

Technical Advantages

We have a team of more than 70 professional engineers who use advanced design software such as UG, AUTOCAD, SOLIDWORKS, etc. to design and perform finite element analysis to ensure the strength and rigidity of the hydraulic press.

Quality Guarantee

The overall warranty of each machine is 1 year. And, the fuselage and cylinder provide a 10-year warranty. In addition, if any accessories are damaged, we will provide free replacements and cover the shipping cost.

After-sale service

PDH has a professional after-sales service department. All of whom have 10 years of experience and can provide 24-hour after-sales service. Answer all your questions promptly.

Certificates

Have various certificates, including "International CE Certification" and "IS09001 Quality Management System Certification".

Competitive Price

There are large-scale machining equipment to support mass production. Located in Xuzhou, it is very close to the port. At the same time, there is government policy support. Therefore, PDH can provide more competitive prices.

PDH Product Categories

Composite Hydraulic Press

Composite hydraulic press is specially designed for composite material compression molding, with high precision, high stability and strong pressure control ability. It is suitable for hot compression molding of SMC, DMC, FRP, GMT, D-LFT, and G-LFT materials, and is widely used in the manufacture of composite products in the power, construction, transportation and other industries.

Deep Draw Hydraulic Press

Deep draw hydraulic press is specially used for deep drawing of metal sheets. It has the characteristics of long drawing stroke, precise pressure control and strong mold adaptability. It is widely used in the automotive, home appliance, kitchenware and other industries to manufacture metal products with complex shapes such as oil pots, wash basins, and auto parts.

Hydraulic Forging Press

Hydraulic forging press is a hydraulic equipment used for metal forging, with high tonnage, large energy output and strong impact capability. It is suitable for die forging, free forging, precision forging and other processes, and is widely used in the high-strength forming production of key metal parts in the fields of automobiles, aviation, rail transportation, etc.

Composite Hydraulic Press

Composite hydraulic press is specially designed for composite material compression molding, with high precision, high stability and strong pressure control ability. It is suitable for hot compression molding of SMC, DMC, FRP, GMT, D-LFT, and G-LFT materials, and is widely used in the manufacture of composite products in the power, construction, transportation and other industries.

Deep Draw Hydraulic Press

Deep draw hydraulic press is specially used for deep drawing of metal sheets. It has the characteristics of long drawing stroke, precise pressure control and strong mold adaptability. It is widely used in the automotive, home appliance, kitchenware and other industries to manufacture metal products with complex shapes such as oil pots, wash basins, and auto parts.

Hydraulic Forging Press

Hydraulic forging press is a hydraulic equipment used for metal forging, with high tonnage, large energy output and strong impact capability. It is suitable for die forging, free forging, precision forging and other processes, and is widely used in the high-strength forming production of key metal parts in the fields of automobiles, aviation, rail transportation, etc.

PDH Production Line

Forging Press Line

We specialize in the manufacturing of high-quality hydraulic forging presses, including hot forging, free forging, open-die, closed-die, and cold forging presses. Beyond standalone machines, we offer complete turnkey forging production lines with full sets of supporting equipment—delivering integrated, reliable solutions tailored to your manufacturing needs.

Dish End Line

A dish end production line is an automated manufacturing facility for metal heads of various shapes and specifications, widely used in industries such as pressure vessels, storage tanks, heat exchangers, and boilers. This line typically includes a blanking system, hot spinning machine, hydraulic bulging machine, cold spinning machine, trimming machine, and automatic loading and unloading system. It features high efficiency, high precision, and a high degree of automation.

Wheel Hub Line

A wheel hub production line is a set of automated processing equipment specifically designed for aluminum alloy or steel wheel hubs, encompassing the entire process from raw material pretreatment, forging/casting, heat treatment, machining, testing, and surface treatment. It is widely used in passenger cars, commercial vehicles, electric vehicles, and high-performance racing vehicles.

Key components include forging press machines, casting equipment, CNC machining centers, X-ray flaw detectors, dynamic balancing machines, and spray/electrophoresis lines. The entire line ensures efficient, precise, and safe wheel hub production.

Forging Press Line

We specialize in the manufacturing of high-quality hydraulic forging presses, including hot forging, free forging, open-die, closed-die, and cold forging presses. Beyond standalone machines, we offer complete turnkey forging production lines with full sets of supporting equipment—delivering integrated, reliable solutions tailored to your manufacturing needs.

Dish End Line

A dish end production line is an automated manufacturing facility for metal heads of various shapes and specifications, widely used in industries such as pressure vessels, storage tanks, heat exchangers, and boilers. This line typically includes a blanking system, hot spinning machine, hydraulic bulging machine, cold spinning machine, trimming machine, and automatic loading and unloading system. It features high efficiency, high precision, and a high degree of automation.

Wheel Hub Line

A wheel hub production line is a set of automated processing equipment specifically designed for aluminum alloy or steel wheel hubs, encompassing the entire process from raw material pretreatment, forging/casting, heat treatment, machining, testing, and surface treatment. It is widely used in passenger cars, commercial vehicles, electric vehicles, and high-performance racing vehicles.

Key components include forging press machines, casting equipment, CNC machining centers, X-ray flaw detectors, dynamic balancing machines, and spray/electrophoresis lines. The entire line ensures efficient, precise, and safe wheel hub production.

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.

About PDH

BEIHUITE Machinery Manufacturing Technology Co., Ltd.(PDH) focuses on the design, manufacturing and process development of high-end hydraulic press equipment. It realizes the full process service from R&D design, manufacturing, sales and after-sales.

Blogs

We have experts in the field of the hydraulic press industry. Here is to share professional information related to the hydraulic press machine and the latest news in the industry. Find more.

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.