Professional Composite Hydraulic Press Manufacturer

As a leading composite hydraulic press manufacturer in China, PDH focuses on delivering high-performance composite molding press solutions tailored to customer needs. Our composite presses are designed for precision, stability, and durability—ideal for producing SMC, BMC, GMT, and other composite parts. With advanced control systems and competitive pricing, we provide reliable equipment to support your efficient, high-quality production. Looking for a cost-effective composite press? Contact us today!

Hydraulic Presses

Contact Us

SMC Insulation Panel Forming Press

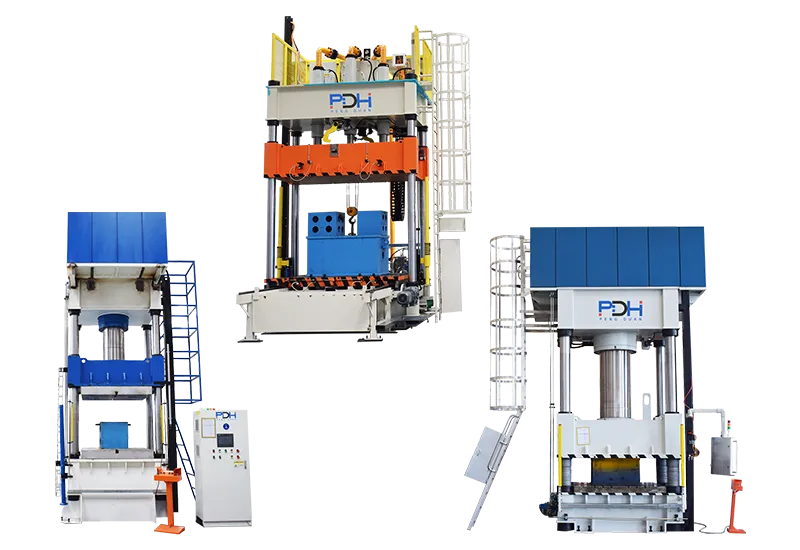

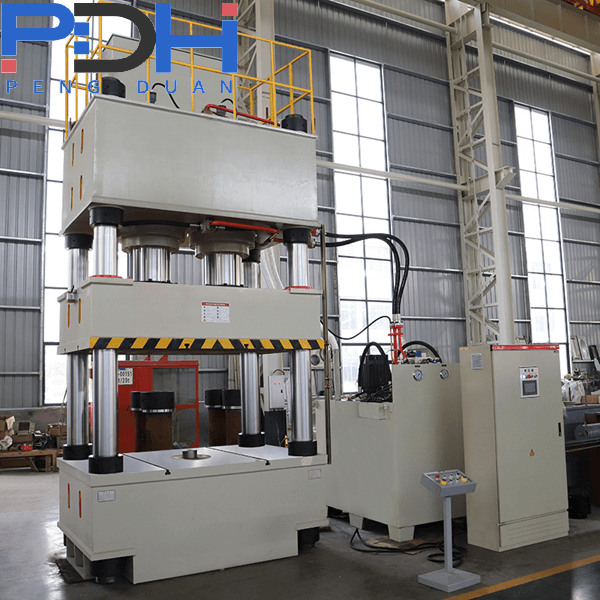

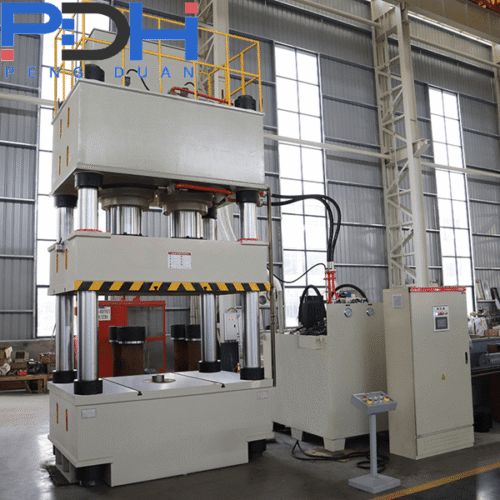

SMC insulation board molding hydraulic presses commonly use 1500-ton, 2000-ton, 2500-ton, 3000-ton, and 4000-ton hydraulic presses. They are available in two structures: three-beam four-column type and frame type. We are a manufacturer of SMC insulation panel-forming presses and can customize SMC insulation board machines to meet process requirements.

Description

SMC insulation panel is also known as SMC molded board, DMC high-pressure resistant board, and unsaturated polyester fiberglass board. It is a plate-shaped product of various colors, made by compression molding an unsaturated polyester fiberglass-reinforced sheet molding compound. The SMC insulation panel molding hydraulic press is specialized hydraulic equipment used to press SMC sheet molding compound into electrical insulation boards in a single process, using high temperature and high pressure.

It provides stable, controllable high-tonnage pressure via a hydraulic system, combined with upper and lower heating molds (hot plates). Within the set temperature, pressure, and holding time, it compresses the SMC material into:

- High-strength

- High insulation performance

- High dimensional accuracy

- Stable surface quality

electrical insulation boards or insulation structural components.

SMC insulation boards possess excellent insulation properties and mechanical strength, and are widely used in substations, power plants, distribution rooms, laboratories, and outdoor live-line work. They are generally available in different specifications, such as 1.25 meters x 2.5 meters with thicknesses ranging from 2mm to 80mm, and 1 meter x 2 meters with thicknesses ranging from 0.5mm to 100mm. Different tonnage hydraulic presses can be selected according to specific needs.

The SMC insulation board forming press is easy to operate and has adjustable working parameters. The system can be equipped with an optional in-mold core pulling control system and a preset in-mold ejection control system. It can perform a series of actions, including rapid descent, segmented pressing, segmented degassing, working, pressure holding, slow mold opening, rapid return, slow demolding, rapid ejection, ejection dwell, and rapid retraction, with multi-point temperature control.

Key Features of the SMC Insulation Panel Forming Hydraulic Press:

✅ 1. Molding pressure specifically designed for insulation boards

- Tonnage range: 500 tons – 3000 tons (larger sizes customizable)

- Uniform pressure distribution ensures consistent board thickness and prevents air bubbles.

✅ 2. Equipped with heating plates for precise temperature control

- Independent temperature control for upper and lower hot plates

- High temperature control accuracy ensures complete resin curing and improves insulation performance.

✅ 3. Stable machine structure

- Common structures: Four-column type / Frame type

- High rigidity and minimal deformation, suitable for continuous production of large-sized insulation boards.

✅ 4. PLC intelligent control

- Pressure, stroke, temperature, and holding time are programmable.

- Molding parameters can be stored, facilitating switching between different insulation board specifications.

Main Application Areas of SMC Insulation Board Forming Hydraulic Presses:

- High and low voltage power distribution cabinet insulation boards

- Transformer insulation boards and partitions

- Insulating structural components for new energy and power equipment

- Composite insulation boards for rail transit and electrical equipment

- Industrial electrical FRP/SMC insulation components

The SMC insulation panel forming press is specialized molding equipment that integrates high-tonnage pressure, precise temperature control, and a stable structure. It is widely used in the production of high-performance insulation boards in the power, electrical, and new energy fields. PDH is a professional hydraulic press manufacturer, offering high-quality composite-material molding hydraulic presses. Please contact us if you have any needs.

Related Products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.