Your Trusted Partner for Forging Press Solutions

As a leading hydraulic forging press manufacturer, we provide complete forging solutions—covering free forging, die forging, hot and cold forging presses. Tonnage ranges from 800T to 5000T, with full customization available to meet your specific production needs. Whether you’re shaping large components or precision parts, our machines deliver strength, stability, and efficiency. Get in touch today to customize your forging press solution!

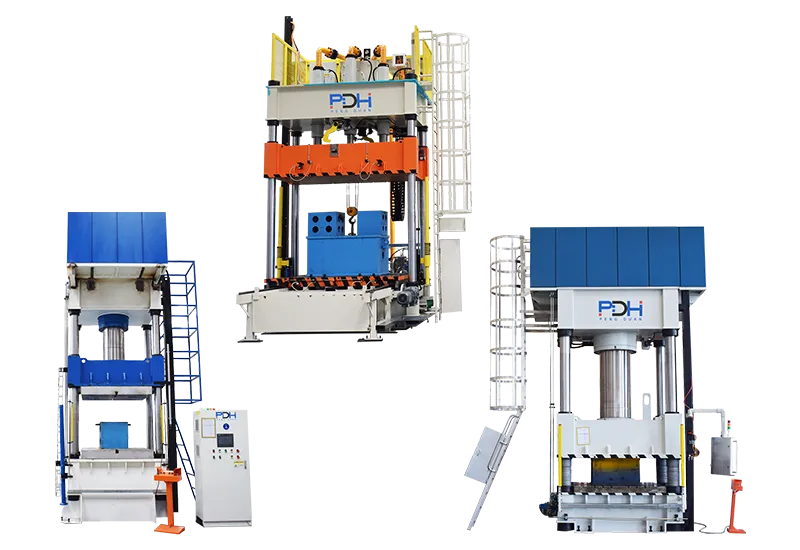

Hydraulic Presses

Contact Us

Alloy Wheel Hub Forging Press

The alloy wheel hub forging press is a specialized industrial machine engineered for high-precision wheel hub manufacturing. By applying high temperature and ultra-high pressure, it plastically deforms metal alloys and forges them into the required wheel hub geometry.

Description

The alloy wheel hub is a critical component in vehicle manufacturing, connecting the wheel assembly to the chassis and directly influencing performance, safety, and aesthetics. Beyond providing structural support for the tire, wheel hubs contribute significantly to vehicle handling, fuel efficiency, suspension behavior, and overall driving stability.

To withstand diverse road conditions and harsh environments, wheel hubs are typically manufactured from high-strength, corrosion-resistant alloy materials. They are widely used in passenger cars, trucks, motorcycles, and high-performance racing vehicles. As the demand for improved vehicle styling and aerodynamic performance grows, the quality standards and manufacturing requirements for alloy wheel hubs have become increasingly stringent.

PDH’s alloy wheel hub forging press is engineered specifically for hub production. With its robust structural design and extremely high forging force, it ensures excellent material flow, superior density, and outstanding product consistency. This makes it the preferred equipment solution for modern wheel hub manufacturers seeking reliability, precision, and high production efficiency.

Features of PDH’s Alloy Wheel Hub Forging Press:

1. High Automation

The hydraulic press offers high levels of automation, enabling continuous production and significantly improving overall manufacturing efficiency.

2. Precision Control

Equipped with advanced control systems, it enables precise regulation of forging temperature, pressure, and deformation, ensuring exceptional product quality and dimensional consistency.

3. Wide Versatility

Designed to accommodate a broad range of wheel hub types and sizes, the machine meets the production requirements of various passenger vehicles, commercial vehicles, motorcycles, and performance cars.

4. High-Strength Material Processing

Capable of forging high-strength alloys, the press ensures the resulting wheel hubs achieve superior durability, mechanical strength, and long-term reliability.

Advantages of Hydraulic Press for Wheel Hub:

-

Increased Production Efficiency

The wheel hub forging press supports high-speed, continuous operation, significantly shortening production cycles and reducing overall manufacturing costs.

-

Enhanced Wheel Hub Design Flexibility

Forging enables the creation of more complex, lightweight hub geometries, thereby improving vehicle handling, performance, and fuel efficiency.

-

High Material Utilization

The forging process maximizes the use of raw materials, minimizes waste, and improves overall resource efficiency.

-

Superior Product Quality

With precise and consistent process control, the hydraulic forging press ensures exceptional dimensional accuracy, mechanical strength, and surface quality—effectively reducing defect rates and enhancing product reliability.

Operation Steps of Wheel Hub Forging Press:

- Heating the metal material: First, the metal alloy material is heated to a certain temperature to make it more plastic. This typically requires operation in a high-temperature furnace.

- Placement into the Mold: Once the metal reaches the proper temperature, it is placed into a mold of a specific shape. The mold is shaped and sized to match the final wheel design.

- Applying pressure: The pressure head of the hub alloy forging press will drop, exerting significant force on the metal. This process is called forging, and it forces the metal into the shape of the mold.

- Cooling and solidification: After forging is complete, the wheel hub is kept in the mold to cool and solidify, ensuring it maintains the desired shape and strength.

- Removing the wheel hub: Finally, the forged and cooled wheel hub is removed and prepared for further machining and processing to achieve its final specifications.

Applications of Wheel Hub Hydraulic Press:

Wheel hub forging machines are widely used in the automobile manufacturing industry, aerospace industry, and other fields that require high-performance alloy wheels. They not only provide high-quality wheel hub manufacturing solutions but also promote continuous innovation in wheel hub design and technology, adapting to evolving needs.

In short, the forging press for alloy wheel hubs is an indispensable piece of equipment in modern manufacturing. Through efficient processes and advanced control systems, it provides high-quality, high-performance wheels for vehicle manufacturing and other related fields, laying a solid foundation for future transportation and engineering applications.

As a professional hydraulic press factory in China, PDH offers high-quality wheel hub forging presses and complete wheel hub production line solutions. If you have any needs, contact us!

Related Products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.