Your Trusted Partner for Forging Press Solutions

As a leading hydraulic forging press manufacturer, we provide complete forging solutions—covering free forging, die forging, hot and cold forging presses. Tonnage ranges from 800T to 5000T, with full customization available to meet your specific production needs. Whether you’re shaping large components or precision parts, our machines deliver strength, stability, and efficiency. Get in touch today to customize your forging press solution!

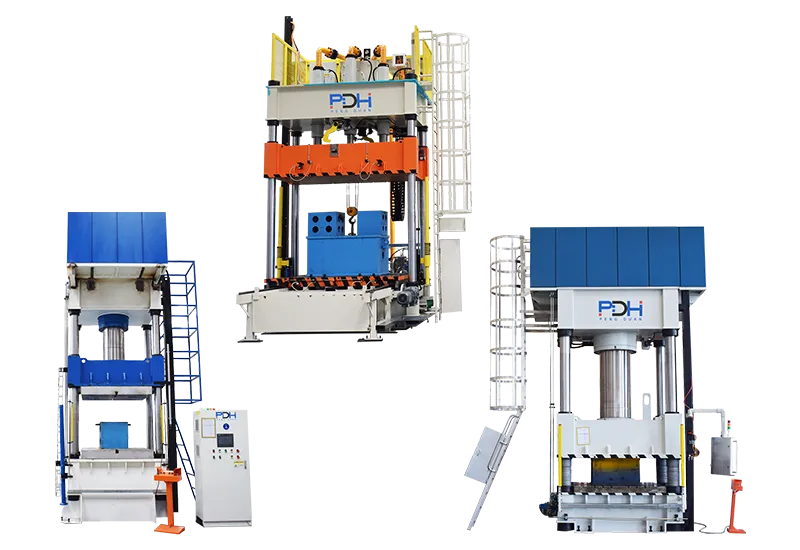

Hydraulic Presses

Contact Us

500T Cold Extrusion Press

Cold extrusion hydraulic presses are mainly used for the cold extrusion shaping of metal materials, as well as for stamping, forming, shallow drawing, shaping, die casting, and trimming of metal or non-metal parts. They are suitable for pressing automotive parts, watch cases, watch straps, eyeglass frames and parts, picture frames, tableware, signs, locks, and hardware components, among others.

Description

Cold extrusion technology is an advanced manufacturing process characterized by high precision, high efficiency, high quality, and low consumption. It is primarily used in the mass production of small and medium-sized forgings. Compared to hot forging and warm forging processes, it saves raw materials, reduces energy consumption, improves production efficiency, enhances the geometric accuracy of parts, and improves the working environment.

Cold extrusion technology has been widely applied across various industrial sectors, including fasteners, machinery, instruments, electrical appliances, light industry, aerospace, shipbuilding, and military industries, and has become one of the indispensable processing methods in metal-plastic volume-forming technology. The cold extrusion hydraulic press is a key piece of equipment in this technology. Cold extrusion hydraulic presses are suitable for the cold forging of aluminum alloys, copper, steel, and other materials.

This article primarily introduces our 500-ton hydraulic press for cold metal extrusion. It is a multi-functional three-beam four-column structure press, belonging to vertical extrusion equipment. It uses high-pressure liquid as the power source, with the maximum working pressure of the main cylinder controlled within 22 MPa. It features high-dimensional accuracy, high material utilization, high production efficiency, and high product strength. Users can customize frame-type or four-column type (cold/hot) extrusion equipment according to their needs.

Characteristics of the 500-ton Metal Cold Extrusion Hydraulic Press:

1) The oil cylinder is made of integral casting, resulting in high structural strength. The cylinder body is precisely ground and machined, providing a high surface finish and high reliability under high-pressure conditions. It has strong impact resistance, making it particularly suitable for metal extrusion forming. It fully meets the pressure requirements of the extrusion process, and the main cylinder nominal force offers various options from 1000KN to 10000KN.

2) The maximum working pressure of the primary cylinder fluid can be controlled within 22MPa, reducing the load on the oil pump, extending the service life of the oil pump, reducing hydraulic vibration, lowering oil temperature, and maximizing equipment stability.

3) The 500-ton metal cold extrusion hydraulic press adopts a double-speed mode. The main cylinder uses a piston-type master-slave cylinder, with the slave cylinder embedded within it. The slave cylinder has a small cross-sectional area, allowing it to drive the main cylinder to move down quickly with a small amount of oil. When the main cylinder approaches the product, the slave cylinder stops working, and the master cylinder provides rapid forming. Under no-load conditions, it achieves low power consumption and fast mold closing, enabling rapid deep drawing with minimal power. It is equipped with an intelligent sensing system and an adaptive mode to support double-speed and single-speed rapid pressing modes, including single-motor dual-system, single-motor single-system, dual-motor dual-system, and multi-system.

4) Large-tonnage equipment uses large-diameter, internally mounted control valves, providing strong oil flow capacity, large flow rate, low pressure loss, and high reliability.

5) The three beam plates of the 500-ton hydraulic cold extrusion press are integrally formed through one-time precision CNC machining. The guide sleeves of the movable beam plate are extended to twice the length of standard guide sleeves, providing strong resistance to eccentric loads, good rigidity, and high precision. A double-nut structure is used to prevent loosening.

6) The cold extrusion press uses non-contact relay control output, resulting in a short system response time and long service life, eliminating the lag in electrical component response caused by residual magnetism in conventional relays.

7) The actuator is controlled by a PLC, and the loading path is adjusted through an intelligent human-machine interface to control the forming process.

8) It offers two options: with and without mold release. The main cylinder provides strong demolding and return force, facilitating the removal of deeply extruded workpieces. After demolding, the rapid return stroke saves idle time.

Applications of the 500-ton Cold Extrusion Press:

This equipment is suitable for the extrusion forming of metal materials, including creating, upsetting, drawing, expanding, and bending of stepped shafts, discs, and gear parts. It is particularly suitable for the extrusion and forging processes of aluminum products. It can also be used for stamping, forming, shallow drawing, and shaping of metal or non-metal parts. Applicable industries include: shaping and positioning of aerospace products, automotive parts, motorcycle parts, picture frames, transmission components, tableware, signs, locks, hardware parts and tools, agricultural machinery parts, and other manufacturing industries.

Main Parameters of the 500-ton Cold Extrusion Hydraulic Press:

| Model/Technical Parameters | 315T | 500T | |

| Nominal Pressure (KN) | 3150 | 5000 | |

| System Pressure (MPa) | 25 | 25 | |

| Slide Stroke (mm) | 400 | 500 | |

| Maximum Opening Height (mm) | 900 | 1200 | |

|

Worktable effective area (mm*mm) |

Left – right (distance between left and right columns) | 700 | 1000 |

| Front – back (distance from the front to the back of the worktable) | 700 | 1000 | |

| Lower cylinder (t) | 30 | 63 | |

| Lower cylinder stroke (mm) | 200 | 300 | |

| Idle downward speed (mm/s) | 320 | 300 | |

| Pressing speed (mm/s) | 16-40 | 15-38 | |

| Return speed (mm/s) | 280 | 280 | |

| Motor power (KW) | 22*2 | 37*2 | |

| Remarks: 1. Includes PLC system and touch screen; 2. Includes oil temperature cooling device; | |||

PDH is a famous forging press manufacturer in China, providing high-quality forging press machines and custom services. Please feel free to contact me!

Related Products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.