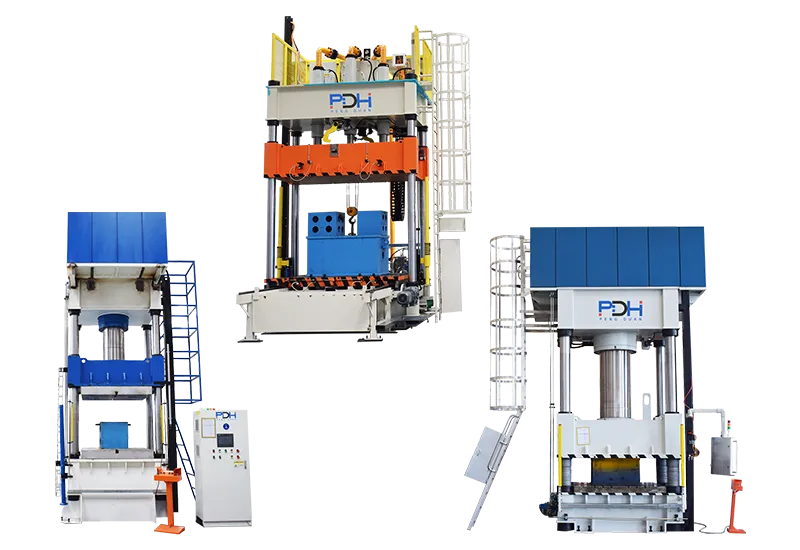

Reliable Deep Drawing Press from a Trusted Manufacturer

Our hydraulic deep drawing press is specially engineered for the precise forming of aluminum, copper, stainless steel, and thin iron sheets. Ideal for deep drawing and press forming of thin metal plates, it delivers reliable performance across a wide range of industries. Contact us today for customized solutions!

Hydraulic Presses

Contact Us

4000T Train Door Forming Hydraulic Press

The 4000-ton train door forming hydraulic press is a three-beam, four-column hydraulic press. It is primarily used for stretching, flanging, bending, and stamping of train doors, and can also be used for general pressing.

Description

Railway train side door panels and freight train door panels are mostly made of steel and manufactured by stamping. The machinery required for stamping freight train door panels generally requires a large tonnage. Commonly used machines include 3000-ton, 4000-ton, and 5000-ton four-column hydraulic presses or frame-type hydraulic presses. The 4000-ton train door panel forming hydraulic press is a widely used model, a four-column structure stamping press.

PDH‘s 4000-ton train door stretching press can be equipped with additional devices, such as blanking buffers, material feeding mechanisms, and movable worktables, as needed. Besides stretching, the hydraulic press can also be used for straightening, pressing, packaging, compacting, and pressing plates. It can also be used for pressing processes of shaft parts, calibration, crimping, and pressing processes of profiles, as well as bending, flanging, shaping, embossing, stamping, stretching, and pressing processes of plastic materials, such as stamping, bending, and thin sheet stretching operations.

Performance Characteristics of the 4000-ton Train Door Panel Forming Hydraulic Press:

1. “Four-dimensional” CNC technology. The control of temperature, curing time, pressure, and speed during product molding is all achieved through PLC computer numerical control. Meanwhile, the control system of the 4000-ton train door forming press uses programmable logic control. The power is reliable, and the program can be easily modified to meet different process requirements. The high degree of automation significantly improves working conditions, reduces waste, and ensures product quality.

2. Soft landing technology. The smooth transition between fast and slow speeds protects the mold and extends its service life, as well as that of the equipment.

3. Adjustable pre-pressing process. According to the product formula’s technical requirements, fluidity during pre-pressing and molding can be numerically controlled, making it more suitable for forming large-area, complex parts with left-right and up-down structures.

4. Multi-stage constant temperature degassing process. This effectively eliminates technical problems such as surface bubbles and shrinkage deformation in the product.

5. It adopts the latest generation of mold clamping and pressure-holding energy-saving technology, reducing energy consumption by 70%. Stable pressure-holding and mold clamping, stepless speed regulation, and multi-directional core pulling technology ensure the product’s strength, density, and compression ratio. By changing the component program and curve, the physical and mechanical properties of molded composite materials can be improved.

6. External mold opening and air ejection demolding processes can be set, ensuring better surface quality of hot-pressed products. This process effectively solves technical problems such as mold expansion, surface roughening, and demolding difficulties in the 4000-ton train door deep drawing press.

Advantages of the 4000-ton Train Door Panel Deep Drawing Hydraulic Press:

1. High pressure. The maximum pressure of this hydraulic press reaches 4000 tons, meeting the high-pressure requirements for forming and ensuring forming quality.

2. Large worktable area. The 4000-ton train door panel forming hydraulic press features a large worktable, accommodating the forming needs of large workpieces and improving production efficiency.

3. Reliable working accuracy. The hydraulic press uses precise pressure sensors and hydraulic system control to ensure working accuracy during the forming process and improve product quality.

4. Easy to operate. The hydraulic press features an advanced digital hydraulic control system that is easy to operate and highly reliable. Operators can operate it after simple training.

5. High efficiency. The 4000-ton train door panel forming hydraulic press is driven by a hydraulic system, enabling high speed and efficiency, and improving overall production efficiency.

6. High degree of automation. The hydraulic press uses an automated control system that automates various forming tasks, reducing labor intensity.

7. Professional application fields. The 4000-ton four-column hydraulic press can be widely used in the forming of large structural parts in industries such as vehicles, rail transit, aerospace, and shipbuilding, meeting the needs of forming production.

Components of the 4000-ton Truck and Train Door Stamping Equipment:

- Hydraulic System: The hydraulic system is a core component of the hydraulic press. It consists of a hydraulic pump, hydraulic motor, hydraulic cylinder, pressure sensor, etc., and is mainly used to power and control the operation of the 4000-ton deep-drawing hydraulic press.

- Mechanical Structure: The mechanical structure comprises the hydraulic press base, frame, workbench, guide columns, connecting rods, molds, and other components. They work together to complete the positioning, fixing, and forming of the workpiece.

- Electrical Control System: The electrical control system includes the hydraulic press controller, motor, distribution box, wiring, sensors, and related components. They control the operation of the 4000-ton four-column hydraulic press and adjust process parameters via electrical signals, current, and voltage.

- Lubrication System: The lubrication system primarily lubricates and cools the hydraulic press’s moving parts, ensuring long-term, stable, and smooth operation.

- Safety Protection Devices: Safety protection devices are an indispensable part of the 4000-ton metal stamping presses. These include emergency stop buttons, safety guardrails, power-off self-locking devices, and leakage protection devices to ensure the safety of operators and equipment.

Process Flow for Stamping Train Door Panels Using a 4000-ton Hydraulic Press:

1. Raw Material Selection: Select suitable materials that meet the strength and wear resistance requirements of the door panels.

2. Mold Manufacturing: Design and manufacture molds for forming the train door panels. The molds should have sufficient strength, precision, and surface finish to meet the forming quality requirements.

3. Material Processing: Cut and pre-process the raw materials according to the size and shape of the door panels for subsequent processing and forming.

4. Material Cleaning: Clean the raw materials to ensure a clean, oil-free surface, improving forming quality.

5. Determination of Process Parameters: Evaluate and determine the mold dimensions, processing methods, and forming parameters to ensure forming quality and production efficiency.

6. Material Placement in the Mold: Place the cut raw materials into the mold according to the set mold configuration, adjusting the mold position and material quantity.

7. Forming Process: Start the 4000-ton train door panel stamping equipment. The mold begins to move, forming the material. Adjust the pressure and speed of the 4000-ton four-column hydraulic press according to actual conditions, and monitor technical parameters in real time during the forming process to ensure quality and efficiency.

8. Inspection and Quality Control: Inspect and quality control the formed train door panels, promptly identifying and addressing any problems to ensure that the finished product meets quality standards and specifications.

9. Subsequent Processing: After forming, perform subsequent processing steps such as deburring, polishing, and painting on the train door panels to meet the final product quality requirements.

Related Products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.