Reliable Deep Drawing Press from a Trusted Manufacturer

Our hydraulic deep drawing press is specially engineered for the precise forming of aluminum, copper, stainless steel, and thin iron sheets. Ideal for deep drawing and press forming of thin metal plates, it delivers reliable performance across a wide range of industries. Contact us today for customized solutions!

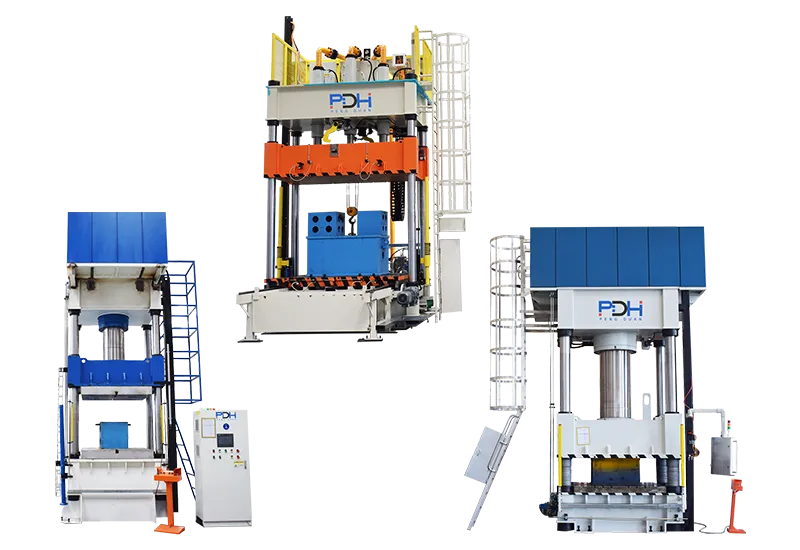

Hydraulic Presses

Contact Us

1000T Metal Trimming Press

The metal hydraulic trimming press uses hydraulic power transmission to perform stamping and trimming operations according to specifications. It is commonly used for trimming automotive parts, removing flash from forged parts, trimming die-cast parts, and trimming stainless steel products. It is also suitable for deburring and shaping various aluminum and magnesium alloy die-cast products.

Description

This article introduces a PDH 1000-ton trimming hydraulic press for metal products. It features a three-beam, four-column, single-cylinder design and is used for trimming automotive parts. It is also a multi-functional press; by changing the molds, it can be used for forming plastic materials, as well as for blanking and drawing sheet metal.

Equipped with a servo system, it surpasses ordinary hydraulic presses in terms of noise, speed, and power consumption, offering advantages such as high efficiency, energy saving, and environmental friendliness. Due to its working characteristics, the metal hydraulic trim press requires the addition of a cushioning cylinder and cushioning pads, and can also be equipped with a leveling system and an automatic mold-changing system.

The 1000-ton metal parts trimming hydraulic press consists of a main machine, hydraulic system, electrical control system, and auxiliary components. The working pressure and stroke range can be adjusted according to process requirements, offering excellent versatility. The equipment is easy to maintain, highly reliable, and features good safety performance, without polluting the environment or endangering human health.

Structure and Performance of the 1000-ton Metal Trim Press:

The 1000-ton hydraulic press for trimming metal parts consists of the main machine, hydraulic system, electrical control system, and auxiliary parts.

1. Main Machine

The main machine consists mainly of the machine body and the main cylinder.

1) Machine Body

The 1000-ton hydraulic press for trimming metal parts has a three-beam, four-column, four-nut structure, which facilitates pre-warning and precision adjustment of the press. The three main beams (upper crossbeam, slider, and base) are made of high-quality 45 steel plates. The slider is connected to the main cylinder piston via a flange, and it moves up and down, guided by four columns. The four-column guide bushings are automatically lubricated with boundary thin oil, improving the friction mechanism, reducing frictional resistance, and preventing scratches and damage to the columns. The machine body consists of the upper beam, slider, workbench, columns, locking nuts, and other components. The main oil cylinder and hydraulic station are arranged on the upper beam.

2. Electrical System

The entire electrical system is divided into a power section and a control section.

1) Power Section

The hydraulic trimming press uses a three-phase five-wire AC 380V power supply. The electrical system consists of a power circuit and a control circuit. The power circuit is 380V, 50Hz three-phase. The control circuit is 24V, 50Hz. The valve control voltage is 24V. A leakage protection device is installed in the electrical cabinet. It consists of an automatic air switch, a circuit breaker, a thermal relay, an AC contactor, and a three-phase squirrel-cage induction motor used to drive the oil pump.

2) Control Section

The electrical control of the metal trim press uses a PLC programmable logic controller as the main control unit. The electrical system has an independent control cabinet. The electrical control box is located in front of the equipment, and its position is confirmed by the customer.

Applications of the 1000-ton Trim Press for Metal Products

The 1000-ton metal trimming machine primarily trims, punches, and shapes hot- and die-forged parts, as well as medium-thick plate-stamped parts. It is widely used in the production of automotive, construction, agricultural, and general machinery components. With sufficient tonnage and stable trimming force, it can efficiently remove flash and burrs from forged parts, ensuring clean edges and consistent dimensions. It is suitable for metal materials, including steel, aluminum alloys, and copper alloys. This equipment can be integrated with hot-forging production lines or automated robotic systems, making it an ideal choice for post-processing and finishing of medium- to large-sized forged parts.

Operation of the 1000-ton Metal Trimming Hydraulic Press:

Automatic Operation:

1. Set the “Working Status Selection” switch to the semi-automatic position. The equipment is now in automatic mode, which is generally used for production.

2. Add the raw materials evenly into the mold cavity according to the process specifications.

3. Press the “Two-Hand Operation” buttons simultaneously. The slider moves down quickly. After reaching the set limit, the slider moves down slowly, and the upper and lower molds close and maintain pressure.

4. After the set time, the slider retracts, releasing pressure and venting air. Once the trimming hydraulic press reaches its highest position, remove the product.

Manual Operation:

1. Set the “Working Status Selection” switch to the manual position. The equipment is now in manual mode.

2. Add the raw materials evenly into the mold cavity according to the process specifications.

3. Press the “Two-Hand Operation” buttons simultaneously. The slider moves down quickly. After reaching the set limit, the slider moves down slowly, and the upper and lower molds close and maintain pressure.

4. After the set time, press the “Mold Opening” button. The slider retracts, releasing pressure and venting air. Once the metal trimming hydraulic press reaches its highest position, press the “Ejector Cylinder Eject” button. The ejector cylinder starts, pushing the product out, and the upper limit indicator light illuminates. After removing the pressed product, press the “Ejector Cylinder Retract” button to retract the ejector cylinder. The lower limit indicator light illuminates, and the entire operation is complete.

Related Products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.