Correct use of machinery and equipment, careful maintenance, and strict implementation of safety operating procedures are necessary to extend the service life of hydraulic press and ensure safe production. Therefore, in addition to being familiar with the structure and performance of the machine, operators should also pay attention to the following points.

1. Hydraulic station commissioning and maintenance require specialized personnel. When disassembling hydraulic components, keep them in a clean area. All sealed surfaces must be free of scratches.

2. Hydraulic oil is the energy transfer medium during the operation of the hydraulic station. The quality, cleanliness, and viscosity of the hydraulic oil play a crucial role in the lifespan of the hydraulic pump, valve, and cylinder. Therefore, when operating the hydraulic station, it is crucial to pay close attention to the quality and cleanliness of the hydraulic oil. The oil used in the hydraulic system must be strictly filtered, and an oil filter should be installed in the hydraulic system.

3. While ensuring regular system operation, the hydraulic pump pressure should be set as low as possible. The back-pressure valve pressure should also be set as low as possible to reduce energy loss and heat generation.

4. To prevent dust and water from entering the oil, the area around the oil tank should be kept clean and regularly maintained.

5. The oil level in the oil tank should always be kept high enough to ensure adequate circulation and cooling of the oil in the system. Care should also be taken to keep the oil tank, oil pipes, and other equipment clean to facilitate heat dissipation. Generally, a safe oil temperature of 30°C to 55°C is considered optimal. This temperature provides optimal performance and the longest life. When the oil temperature exceeds 60℃, its service life will be halved for every 8℃ increase.

6. Avoid dropping the pressure below atmospheric pressure at any point in the system. Use good sealing devices. Replace any seal failure promptly. Regularly tighten all load-bearing screws, such as the cylinder guide screws and piston rod flange screws, to prevent loosening. Prevent air from entering the hydraulic system and causing oil leakage.

7. For systems using water coolers, ensure adequate cooling water flow and unobstructed piping. For systems using air coolers, ensure adequate ventilation. Prevent excessive oil temperatures.

8. For systems with filters, clean or replace the filter element regularly (approximately once a month) to prevent clogging and rapid oil temperature rise, which can cause rupture of the hydraulic components or the oil pump.

9. The system operating pressure is set by a pressure regulating valve to adjust the hydraulic pump’s output pressure. Generally, the set pressure should not exceed the original design rating. Failure to do so may result in damage to the hydraulic pump, seizure of the hydraulic valve, or motor burnout.

10. To ensure reliable operation of the press, it is recommended that certain press components be replaced at the end of their service life. Record and document any major issues resolved and unresolved during maintenance. This will serve as a reference for the next maintenance or overhaul schedule.

11. Record and document any major issues resolved and unresolved during maintenance. This will serve as a reference for the next maintenance or overhaul schedule.

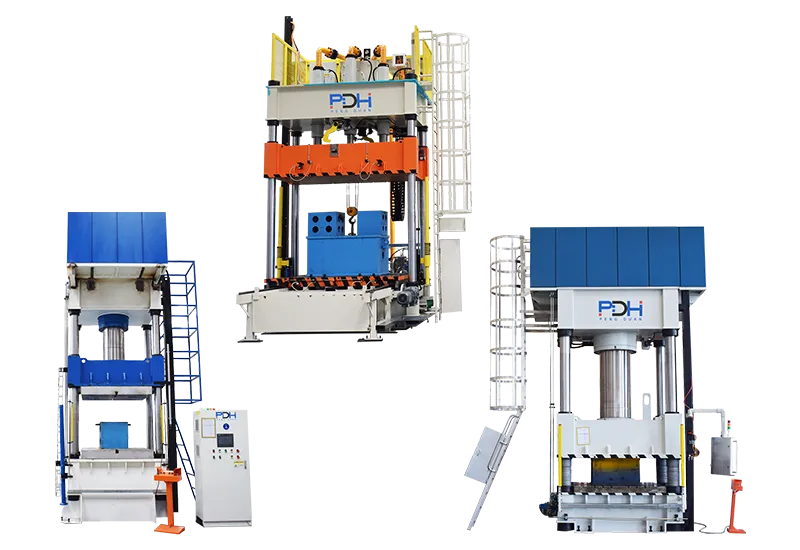

PDH is a renowned hydraulic press factory in China. We not only offer a wide range of hydraulic press equipment, but also provide professional maintenance information and precautions. We offer comprehensive assistance to help customers optimize the use of hydraulic presses. Contact us for more information.