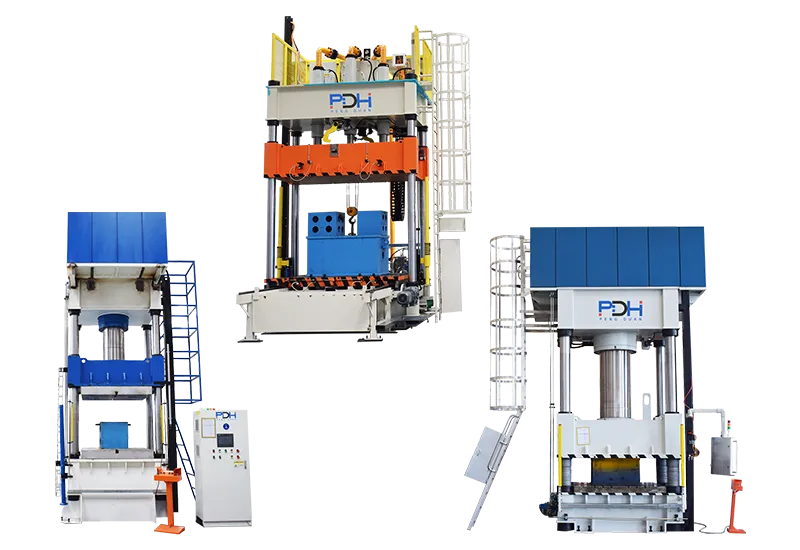

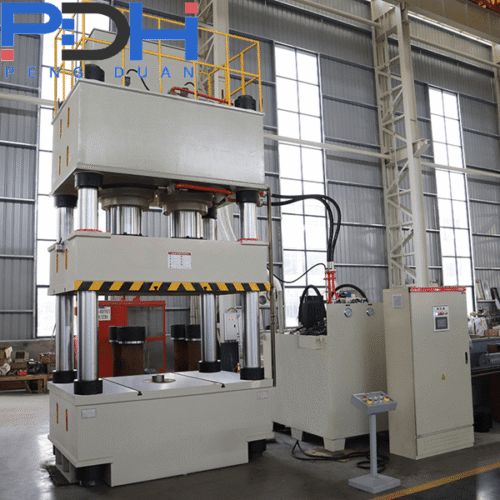

Professional Composite Hydraulic Press Manufacturer

As a leading composite hydraulic press manufacturer in China, PDH focuses on delivering high-performance composite molding press solutions tailored to customer needs. Our composite presses are designed for precision, stability, and durability—ideal for producing SMC, BMC, GMT, and other composite parts. With advanced control systems and competitive pricing, we provide reliable equipment to support your efficient, high-quality production. Looking for a cost-effective composite press? Contact us today!

The Best Composite Molding Hydraulic Press for Sale

he composite hydraulic press is specially designed for the compression molding of thermosetting and thermoplastic composite materials. By applying high pressure and heat through specially designed molds, it enables the efficient molding of composite parts in various shapes, colors, and performance grades, based on different product formulas and mold designs.

This press is ideal for processing materials such as SMC, BMC, DMC, FRP, GMT, D-LFT, and G-LFT. Featuring high efficiency, advanced configurations, excellent reliability, and low energy consumption, our composite presses are widely used across industries such as marine, construction, petrochemicals, energy, electrical appliances, telecommunications, rail transit, and aerospace.

Set a Consultation Today

Application Of Composite Hydraulic Press

Composite hydraulic presses are widely used for the molding and forming of various composite products such as tempered glass backboards, SMC/GRP water tanks, meter boxes, trash bins, cable brackets, cable ducts, automotive parts, septic tanks, and resin drainage covers. These machines are ideal for applications across multiple industries, including shipbuilding, automotive manufacturing, electrical appliances, rail transit, and aerospace, where high strength, corrosion resistance, and lightweight materials are essential.

Car Roof

FRP Panel

GRP Boxes

Why Choose PDH

Processing Capabilities

PDH currently has more than 140 sets of advanced processing, testing and measuring equipment, including nine-axis machining center, large CNC gantry machining center, large heat treatment equipment, large lathe and others.

Technical Advantages

We have a team of more than 70 professional engineers who use advanced design software such as UG, AUTOCAD, SOLIDWORKS, etc. to design and perform finite element analysis to ensure the strength and rigidity of the hydraulic press.

Quality Guarantee

The overall warranty of each machine is 1 year. And, the fuselage and cylinder provide a 10-year warranty. In addition, if any accessories are damaged, we will provide free replacements and cover the shipping cost.

After-sale service

PDH has a professional after-sales service department. All of whom have 10 years of experience and can provide 24-hour after-sales service. Answer all your questions promptly.

Certificates

Have various certificates, including "International CE Certification" and "IS09001 Quality Management System Certification".

Competitive Price

There are large-scale machining equipment to support mass production. Located in Xuzhou, it is very close to the port. At the same time, there is government policy support. Therefore, PDH can provide more competitive prices.

General FAQs

The warranty period is calculated from the date when the equipment passes the acceptance inspection by both parties, and the warranty period is one year. During the warranty period, if there are any non-man-made quality problems with the non-wearing parts of the machine, we will send new spare parts for a replacement for free.

Generally, we accept T/T, L/C, D/D and D/P payment. If you are our special customer, we can accept better payment methods.

Export standard packaging. If there are wooden boxes, export-free, fumigation-free wood should be used.

The production will be completed within 2-3 months after the contract is signed and the advance payment is received. Delays due to payment reasons are the buyer’s responsibility.

The production will be shipped within 2-3 months after the contract is signed and the advance payment is received. Delays due to payment reasons are the buyer’s responsibility.

In general, we can directly solve a lot of problems through video. For small problems during the use of the machine, we will arrange mechanical engineers to help you solve them remotely, and provide one-to-one guidance, such as sending text instructions or videos, to teach you how to solve the problem. If the part that needs to be replaced is within the warranty period, we will send it to you free of charge. Of course, you can also buy locally (if you can), which saves even more time. For more serious problems, if the way of remote guidance does not work, we will arrange an on-site engineer service. In areas where there are agents, we will directly contact the agents to provide services.

Related Blog for Composite Hydraulic Press

Request a Quote

Want to learn more about composite hydraulic presses? Please fill out the form below to contact us now. Our staff will reply to you within 24 hours.

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.