Reliable Deep Drawing Press from a Trusted Manufacturer

Our hydraulic deep drawing press is specially engineered for the precise forming of aluminum, copper, stainless steel, and thin iron sheets. Ideal for deep drawing and press forming of thin metal plates, it delivers reliable performance across a wide range of industries. Contact us today for customized solutions!

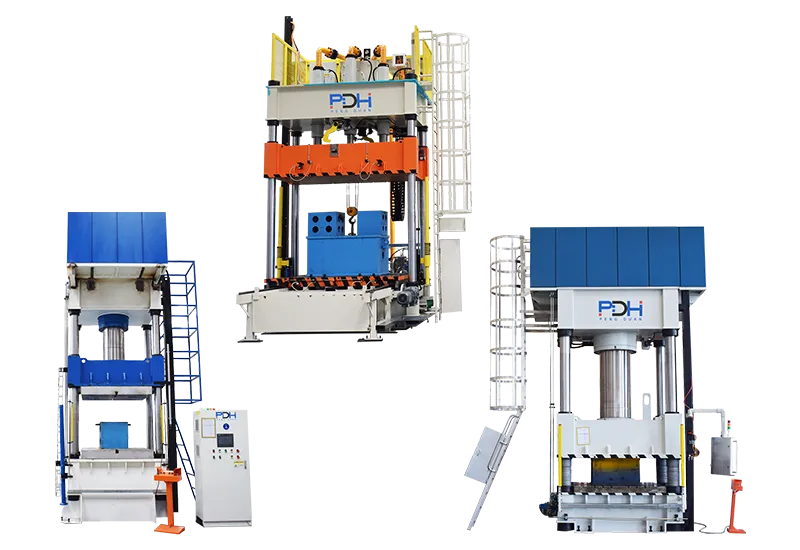

Hydraulic Presses

Contact Us

200T Thin Plate Stretching Hydraulic Press

The 200-ton stretching press is primarily used for stretch forming metal sheets and thin-walled parts. It is suitable for industries such as automotive parts (e.g., car doors, hoods), home appliances, and hardware products. Its core configuration includes a servo system, a hydraulic cushion device, and PLC control, enabling processing of shallow-drawing, deep-drawing, and complex-shaped parts.

Description

The 200-ton hydraulic press for sheet metal stretching, bending, and stamping is specifically designed for these operations. It features an integral welded machine body, 45° guide rails and sliders, and imported sealing components. Equipped with an advanced cartridge-valve hydraulic system, it is widely used in the automotive, aerospace, and chemical industries, delivering high precision and durability.

PDH‘s thin-plate stretching hydraulic presses are primarily used for processes such as stretching, bending, flanging, and forming various types of sheet metal. In terms of machine structure, they are mainly divided into two types: four-column and frame type. The four-column structure is simple, economical, and practical, suitable for various stretching processes. The frame-type structure offers good rigidity, high precision, and strong resistance to eccentric loads, making it suitable for stretching processes requiring high precision. We can manufacture sheet-metal stretching presses that meet our customers’ specific requirements, including the shape, size, and material of the stretched workpiece.

Here, we mainly introduce our 200T frame-type single-acting sheet metal stretching hydraulic press.

Features of the 200T Frame-Type Single-Action Thin Plate Stretch Hydraulic Press:

◇ Adopts a frame structure, offering good rigidity, high precision, and strong resistance to eccentric loads.

◇ Utilizes an integrated cartridge valve system, resulting in fewer leakage points, reliable operation, and a long service life.

◇ The oil cylinder is forged from high-quality 45# carbon forged steel. Its inner surface is processed by roller burnishing. The hydraulic cylinder possesses sufficient strength and rigidity. The main oil cylinder uses imported sealing components to ensure reliable sealing performance.

◇ Employs a PLC-controlled electrical system with a compact structure, sensitive and reliable operation, and good flexibility.

◇ Working pressure and stroke can be adjusted within the specified range according to process requirements, making the operation simple.

◇ Can achieve two forming processes: constant pressure and constant stroke, and has a pressure-holding delay function with adjustable delay time.

◇ The stretching and blank holder slides can be connected as one unit via positioning pins to achieve single-action process movements.

◇ Uses centralized button control, offering three operating modes: adjustment, manual, and semi-automatic.

Technical Parameters of the Single-Action Sheet Metal Forming Hydraulic Press

|

Sheet Metal Forming Hydraulic Press |

|||||||

| Project | Unit | 100T | 200T | 315T | 400T | 500T | 630T |

| Liquid Pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 |

| Slider Effective Stroke | mm | 500 | 700 | 800 | 900 | 1200 | 1200 |

| Opening Height | mm | 800 | 1100 | 1250 | 1500 | 1800 | 1800 |

| Work Table Effective Area | mm*mm | 630*550 | 750*700 | 660*600 | 1000*1000 | 800*800 | 1260*1160 |

| Idle Downward Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 120 |

| Pressing Speed | mm/s | 5-10 | 5-15 | 5-10 | 5-10 | 5-10 | 8-15 |

| Return Speed | mm/s | 300 | 300 | 300 | 300 | 300 | 300 |

| Motor Power | KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 22 |

| Ejection Force | t | 200 | 200 | 400 | 400 | 400 | 630 |

| Ejection Stroke | mm | 200 | 300 | 200 | 220 | 220 | 300 |

Applications of 200T Thin-plate Stretching Hydraulic Presses:

- Automotive parts: body panels, brake pads, fuel tanks, chassis, axle housings, bumpers.

- Household appliance parts: washing machine, rice cooker, television, refrigerator, etc.

- Kitchenware: sinks, kettles, stainless steel utensils, and various other containers.

Optional Accessories:

1. Mobile workbench

2. Punching buffer device

3. Photoelectric safety device

4. Material feeding device

5. PLC programmable controller

6. Mold heating and temperature control device

7. Touchscreen industrial display

8. Hydraulic system heating and cooling device

Detailed Information on the Sheet Metal Stretching Machine

1) Sheet Metal Deep Drawing Machine Body

① The 200-ton frame-type sheet metal stretching hydraulic press features an integral frame structure.

② Side windows are provided between the left and right columns.

③ It adopts a high-quality steel plate welded structure, and the welded parts are annealed after welding to fully eliminate welding deformation and stress, ensuring that the welded parts remain durable and do not deform.

2) Slider of the Frame-Type Thin Panel Stretching Press

① The slider uses 45° guide rails for guidance. Four guide plates are installed on the left and right columns.

② The slider’s guide rails move vertically on the guide plates. The motion guidance accuracy is adjusted by the wedge on the slider guide rail to ensure parallelism with the moving worktable. Adjustment is convenient and highly accurate.

③ After adjustment, the accuracy is well-maintained, and it has strong resistance to eccentric loads.

3) Hydraulic System of the Sheet Metal Forming Hydraulic Press:

① The hydraulic system is installed on the right side of the hydraulic press machine body.

② The hydraulic system adopts a cartridge integrated system, ensuring sensitive operation, reliable performance, and good sealing.

③ The hydraulic press pump station consists of an oil tank, high-pressure pump, electric motor, and cartridge valves. The oil tank is welded from steel plates. It is a closed-type oil tank with separate suction and return oil areas. The oil tank is equipped with a cleaning window and a drain plug for convenient cleaning and oil changes. The hydraulic press’s oil pump suction port is equipped with a direct-flow suction oil filter to ensure oil cleanliness and extend the service life of the pump and valves.

④ The hydraulic system has reliable sealing, preventing leakage. The hydraulic press’s main pipelines use flange connections and anti-vibration pipe clamps.

4) Electrical Control System of the Single-Acting Thin Plate Stretching Press Machine:

① Independent electrical cabinet. It houses the electrical control system, including circuit breakers and relays.

② Various alarm signals and limit switches of the press are programmatically interlocked with the press’s actions.

③ The hydraulic press is equipped with a centralized control panel, which contains the necessary operating buttons and selector switches.

As a famous hydraulic press factory in China, PDH offers high-quality and various types of metal forming press machines that can meet customers’ needs. If you have a request, please feel free to contact us!

Related Products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.