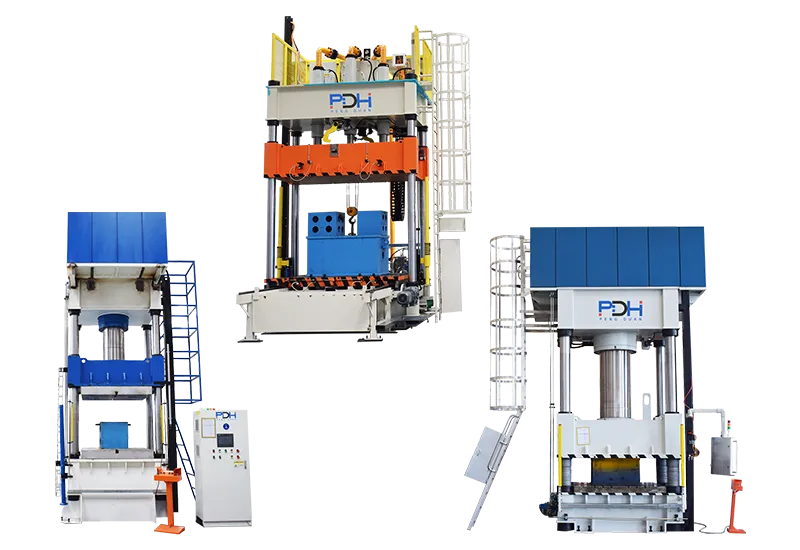

Hydraulic presses are indispensable equipment in the mechanical manufacturing and processing industry. They come in a wide variety of structural types. Different hydraulic presses, depending on their intended use, have distinct structural forms.

Types of Hydraulic Press Structures

Based on their architecture, hydraulic presses fall into two main categories: vertical and horizontal. Based on their composition, they can be classified as column type, single-arm type, and frame type. Column-type hydraulic presses are further classified as four-column, two-column, three-column, and multi-column. Furthermore, based on the number and arrangement of hydraulic cylinders, hydraulic presses are classified as single-cylinder, three-cylinder, or multi-cylinder.

1) Horizontal Press Machine

The horizontal press machine is a multi-functional machine tool with a horizontally acting hydraulic cylinder and press head. By changing molds, it can perform operations such as shearing, sheet-metal bending, pipe bending, and punching. It features a double-column guide and double-sliding-block fixture mounting. It is suitable for pressing spline shafts or flanges of various automotive drive shafts.

The equipment is easy to operate, with sensitive movements and high concentricity accuracy during pressing. The main body of the horizontal press machine is made of cast steel to prevent deformation. It uses an independent hydraulic system and a movable control box, making it convenient for operators, reducing labor intensity, and enabling quick, easy fixture changes.

2) Frame-Type Hydraulic Press

The machine body is available in both integral and modular designs. It features a four-corner, eight-sided guide rail design, offering advantages such as high precision and strong resistance to off-center loads. The slider primarily uses 45°-inclined guide rails to ensure high guiding accuracy. It offers fast downward slider speed, a large worktable area, and counter-stretching functions for both the upper slider and the lower hydraulic cushion.

It has a wide range of applications and can perform processes such as stretching, blanking, bending, and flanging of thin metal sheets. It is especially suitable for automotive components, including wheel rims, car bodies, axle housings, chassis, and doors.

3) Four-Column Hydraulic Press

This hydraulic press is suitable for plastic pressing processes. Examples include powder and plastic product molding; cold (hot) extrusion metal forming; sheet metal stretching; and cross-pressing, bending, flanging, and straightening. The four-column hydraulic press provides equal pressure distribution. Its advantages include flexibility, versatility, smooth operation, ease of use, quick installation and maintenance, and low cost.

Four-column hydraulic presses can be divided into four-column two-beam presses, four-column three-beam presses, and four-column four-beam presses.

4) Single-Column Press

The single-arm hydraulic press is also known as a C-type hydraulic press. The main body of this press has a C-shaped single-arm structure. It offers an extended working range, utilizing three-sided access. The hydraulic cylinder stroke ranges from 260 mm to 800 mm. The working pressure can be preset. It features a hydraulic system cooling device. The advantages of the single-column hydraulic press are its excellent rigidity, guiding performance, speed, and high precision.

5) Gantry Press

Depending on the type of fluid used to transmit power, it uses a gantry-type, all-steel, rigid structure that undergoes vibration aging to minimize mechanical deformation. The frame design utilizes finite element analysis, resulting in high rigidity and high precision. It can be used for assembly, disassembly, straightening, rolling, stretching, bending, punching, and other operations on machine parts, delivering multi-purpose functionality in a single machine.

The gantry hydraulic press worktable moves up and down, increasing the machine’s opening height and making it easier to use.

Hydraulic Press Applications Types

- Composite Material Forming Hydraulic Press: Used for producing various composite material products.

- Forging Hydraulic Press: Used for free forging, ingot blooming, and die forging of ferrous and non-ferrous metals.

- Metal Stretching Hydraulic Press: Used for stamping and stretching various thin and thick plates, including single-acting, double-acting, and rubber die stamping.

- Extrusion Hydraulic Press: Used for extruding various non-ferrous and ferrous metal wires, tubes, rods, profiles, and for drawing and punching processes.

- Hot Platen Hydraulic Press: Used for pressing plywood, particleboard, fiberboard, and insulation boards.

- Powder Press: Used for pressing and forming various powder products, such as powder metallurgy, artificial diamonds, refractory bricks, carbon electrodes, plastics, and rubber products.

- Baling and Compacting Hydraulic Press: Used for compacting and baling metal chips and scrap, and baling non-metallic waste.

- Straightening and Press-fitting Hydraulic Press: Used for part straightening and assembly.

As a leading hydraulic press factory in China, PDH not only provides various types and structures of hydraulic presses but also offers professional knowledge and a range of services related to hydraulic presses. If you have any needs, please contact us immediately.