Choosing the right hydraulic press is a critical decision for manufacturers. The right machine can improve product quality, reduce energy consumption, and ensure long-term production stability. The wrong choice, however, often leads to defects, downtime, and unnecessary costs.

With decades of application experience in hydraulic presses for composite materials and industrial forming, this guide explains how to select a hydraulic press that truly matches your production needs.

1. Clarify the Molding Process Requirements

Different processes have very different requirements for the hydraulic press’s structure and performance. For example, SMC/BMC molding typically requires a hydraulic compression molding press with functions such as constant pressure, degassing, and multi-stage pressurization, whereas forging processes place greater emphasis on the equipment’s rigidity and instantaneous load-bearing capacity.

Molding process type

| Manufacturing Processes | Recommended Hydraulic Press Types |

| SMC / BMC molding | Four-column hydraulic press / Frame-type hydraulic press |

| Composite material hot pressing | Servo hydraulic press / Hydraulic press with heating plates |

| Metal drawing | Four-column or frame-type stretching hydraulic press |

| Forging / Die forging | Forging hydraulic press (high rigidity) |

| Straightening / Press fitting | C-type or single-arm hydraulic press |

2. Choosing the Appropriate Tonnage

The “tonnage” of a hydraulic press refers to the maximum pressure the equipment can output. It is one of the most important specifications, but “bigger” does not always mean “better.”

The correct formula is:

Required tonnage = Molding pressure × Projected area of the product × Safety factor

For composite materials:

BMC molding pressure: typically 8–12 MPa

SMC molding pressure: typically 10–15 MPa

The required tonnage depends on:

- Material type

- Product projected area

- Molding pressure

- Safety margin

Undersized presses may cause:

- Incomplete filling

- Surface defects or bubbles

- Inconsistent mechanical strength

Oversized presses may lead to:

- Higher energy consumption

- Faster mold wear

- Increased investment cost

✔ A properly calculated tonnage ensures stable quality and efficient production.

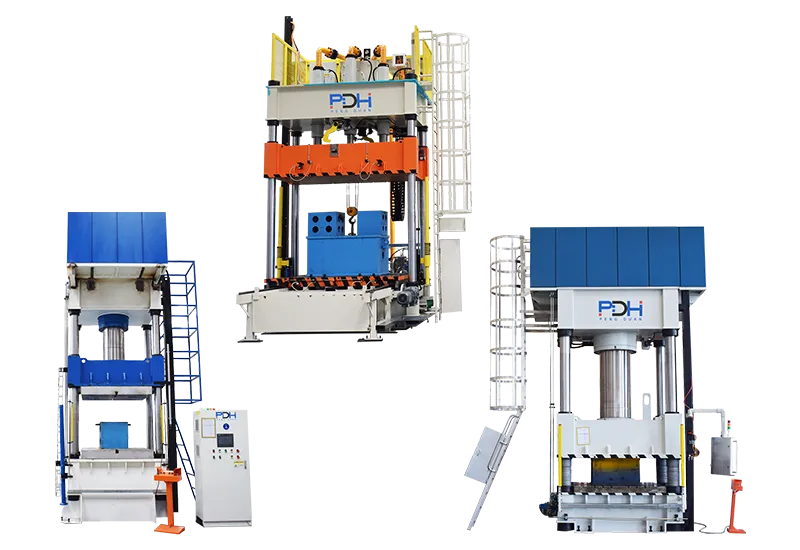

3. Common Structures of Hydraulic Presses

Hydraulic presses are primarily classified by structural type: single-column (C-type) hydraulic press, four-column hydraulic press, frame hydraulic press, gantry hydraulic press, servo hydraulic press, etc.

1) Four-column hydraulic press

- Mature structure, widely used

- Relatively low cost

- Convenient mold change

Suitable for:

Standard molds, SMC/BMC conventional products, mass production

2) Frame hydraulic press

- High overall rigidity

- Strong resistance to eccentric loads

- More uniform pressure distribution

Suitable for:

Large products, high-precision molding, high-tonnage forming

4. Stroke, Opening, and Worktable Dimensions Are Equally Important

In actual selection, many users only focus on tonnage, but neglect the following key parameters:

- Maximum opening height: Determines whether the mold can be installed

- Slide stroke: Affects clamping and demolding operations

- Worktable dimensions: Must match the mold’s external dimensions

Best practice:

Always select the hydraulic press based on mold dimensions, not assumptions.

5. Control System: Where Efficiency Meets Quality

Modern hydraulic presses are no longer “simple machines.” Advanced control systems significantly improve production consistency.

Common features include:

- PLC + touchscreen control

- Multi-stage pressure and speed control

- Recipe storage for different products

- Automatic and semi-automatic operation

For continuous production lines, servo hydraulic systems offer:

- 20–40% energy savings

- Higher pressure control accuracy

- Lower noise and oil temperature

This is especially important for overseas customers focused on energy efficiency and operational cost.

6. Choosing an Excellent Hydraulic Press Manufacturer

When purchasing a suitable hydraulic press, it’s important to consider not only the equipment itself but also the manufacturer’s overall capabilities. These include:

- Industry application experience

- Understanding of manufacturing processes

- Customized design capabilities

- After-sales service and technical support

An experienced manufacturer can help customers avoid trial-and-error costs and achieve faster project success.

Conclusion: Make the Right Choice from the Start

A hydraulic press is a long-term investment. Choosing the right one means:

- Better product quality

- Lower production cost

- Stable and reliable operation

If you are planning a new project or upgrading your production line, working with an experienced hydraulic press manufacturer can make all the difference.

👉 Contact us to discuss your application and receive a customized hydraulic press solution tailored to your market and production needs.