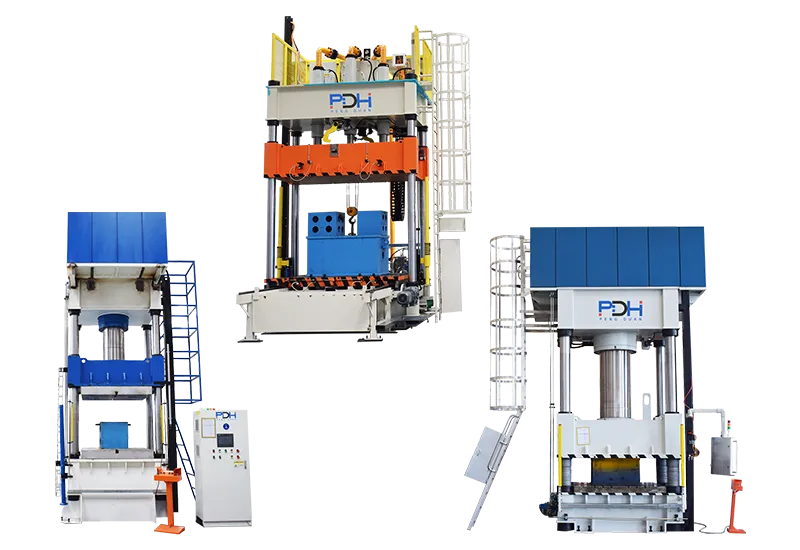

Professional Composite Hydraulic Press Manufacturer

As a leading composite hydraulic press manufacturer in China, PDH focuses on delivering high-performance composite molding press solutions tailored to customer needs. Our composite presses are designed for precision, stability, and durability—ideal for producing SMC, BMC, GMT, and other composite parts. With advanced control systems and competitive pricing, we provide reliable equipment to support your efficient, high-quality production. Looking for a cost-effective composite press? Contact us today!

Hydraulic Presses

Contact Us

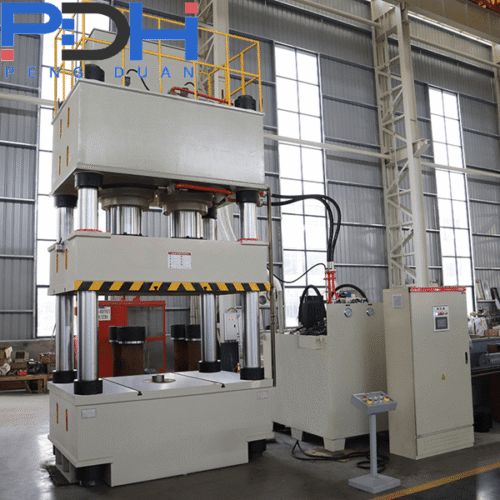

1000T Wood Chip Pallet Hydraulic Press

The wood chip pallet hydraulic press features low noise and no pollution, making it an ideal equipment for one-piece molded pallet production. It is energy-efficient, highly stable, and offers high production efficiency. The equipment is versatile; by changing the molds, it can also produce molded pallets of other styles and materials.

Description

Wood chip pallets are also known as molded plant fiber flat industrial pallets, environmentally friendly molded plant fiber straw pallets, and new fumigation-free environmentally friendly molded pallets. A wood chip pallet hydraulic press is a piece of hydraulic equipment specifically used to manufacture wood chip pallets. It utilizes a molding process that uses wood chips, straw, and waste chemical fibers as raw materials. After pretreatment, these materials are mixed with a binder and injected into a mold. Under high pressure and high temperature, the wood chips and binder are solidified into a single unit, forming a wood chip pallet.

The wood pallet hot-press molding machine features a well-designed structure. It utilizes synchronous positioning, mold closing, and rapid liquid filling and pressurization, achieving full pressure within 35 seconds. Operation is convenient and simple. Simply spread the wood chips evenly in the processing mold, press the work button, and the wood pallet hot press hydraulic machine will automatically complete the entire process of pressurization, pressure limiting, downward pressing, pressure holding, timing, pressure release, demolding, and upward movement to the final position. The pressure holding and curing time for one pallet is approximately 7-10 minutes. The total design pressure is 1000 tons, with four hydraulic cylinders. The molded pallets have high density and an aesthetically pleasing appearance. It is suitable for small-scale production needs and can also be used in conjunction with multiple machines for larger-scale processing.

Based on the specifications and dimensions of wood-molded pallets, commonly used hydraulic presses include 1000, 1250, 1200, 1800, and 2000 tons.

Wood Chip Pallet Raw Materials:

Waste wood, wood chips, sawdust, wood shavings, logs, lumber, branches, wood pieces, straw, waste kraft paper, bamboo, palm trees, coconuts, cork, wheat straw, sugarcane bagasse, corn stalks, and discarded pallets can all be used to produce wood chip pallets.

Molded Wood Pallet Production Process:

Characteristics of the Wood Chip Pallet Hydraulic Press:

1. The machine body adopts a computer-optimized design and is a full steel plate frame structure. It undergoes furnace tempering or vibration aging treatment, ensuring good precision retention.

2. The slider of the molded wood chip pallet hydraulic press uses X-shaped 45° guide rails. It offers good guidance adjustment accuracy, high rigidity, and strong resistance to eccentric loads. The slider operates at high speed, resulting in high working efficiency.

3. The hydraulic control system uses an integrated cartridge valve system, ensuring reliable operation, large flow rate, low internal leakage, and long service life. The system is highly integrated, reducing the need for connecting pipelines and leakage points.

4. The working pressure of the slider, the range of rapid downward movement under no load, and the slow working stroke of the wood chip pallet hydraulic press can all be adjusted according to process requirements.

5. The control system uses an industrial touchscreen PLC operating system, allowing for touchscreen setting of various system parameters and real-time status monitoring. Both manual and automatic operation modes are available.

Advantages of Wood Chip Pallet Forming Presses

- Wide range of applications: Any material containing long fibers can be used to make pallets with this equipment, reducing raw material investment costs.

- High pressure ensures strong and reliable pallets.

- The 1000-ton wood chip pallet molding press can be customized with either a four-column or frame structure. The four-column hydraulic press has a simple and economical structure and is often used for pallets where high precision is not required. The frame-type hydraulic press has high body strength, strong resistance to eccentric loads, and high stamping accuracy, making it suitable for high-standard wood chip pallet molding processes.

- Dual PLC and servo hydraulic control system. One-button operation for pressing, removal, and forming. High efficiency and large output.

- The mold can be easily removed and replaced according to user needs, allowing the production of various product specifications and models, ensuring product diversification and enabling multi-functional use of a single machine.

Applications of Molded Pallets

Molded pallets have a wide range of uses and are suitable for packaging, transportation, and handling goods across various industries, including building materials, electrical appliances, hardware, food, chemicals, furniture, and machinery. They are particularly suitable for use in containerized transport. They can also be used for mechanized loading and unloading in trains, trucks, airplanes, and ships, making them an ideal tool for warehousing, transportation, logistics, and import/export trade.

As a professional hydraulic press factory in China, PDH offers high-quality hot presses and composite material press machines. Moreover, we supply metal stamping presses, forging machines, and related equipment. If you have any needs, please feel free to contact us!

Related Products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.