Professional Composite Hydraulic Press Manufacturer

As a leading composite hydraulic press manufacturer in China, PDH focuses on delivering high-performance composite molding press solutions tailored to customer needs. Our composite presses are designed for precision, stability, and durability—ideal for producing SMC, BMC, GMT, and other composite parts. With advanced control systems and competitive pricing, we provide reliable equipment to support your efficient, high-quality production. Looking for a cost-effective composite press? Contact us today!

Hydraulic Presses

Contact Us

FRP/GRP Water Tank Panel Pressing Machine

The FRP/GRP water tank panel press is a hydraulic forming machine specifically designed for producing FRP/GRP (glass reinforced plastic) water tank panels. Using a high-temperature, high-pressure molding process, it converts SMC (sheet molding compound) into various specifications of water tank panels, ensuring the panels’ high strength, corrosion resistance, aging resistance, and excellent sealing properties. These panels are widely used in construction, industry, and domestic water supply systems.

Description

Fiberglass reinforced plastic (FRP) water tanks are widely used in fire protection, water treatment, building water supply and drainage, and industrial liquid storage due to their lightweight, corrosion-resistant, leak-resistant, and long lifespan. The key to their molding process lies in using a hydraulic press to apply uniform pressure to the fiber layer, eliminating air bubbles in the resin, promoting the resin curing reaction, and ensuring the tank’s structural strength and airtightness.

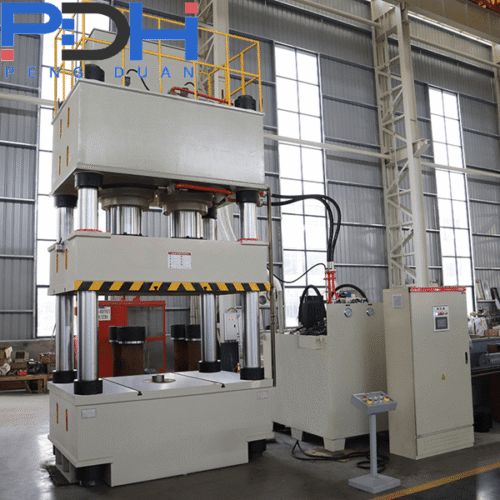

PDH‘s 800-ton FRP water tank molding hydraulic press features a computer-optimized design and an all-steel plate structure. It employs advanced hydraulic transmission technology and control systems to ensure consistent molding precision. The automated control system is easy to operate and learn. The slide and work surface maintain high parallelism accuracy, and the slide speed and pressure are adjustable. Comprehensive safety features and a cooling system ensure safe and reliable operation.

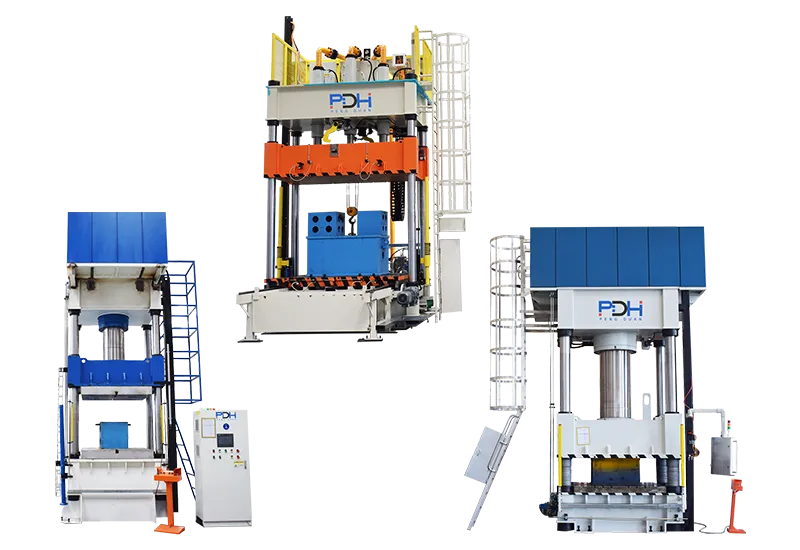

The 800-ton FRP/GRP tank panel molding machine is widely used in the compression molding of FRP water tanks, FRP storage tanks, FRP pipes, and other products. It efficiently completes the compression molding of water tank panels during production. By replacing molds with different shapes, a single press can produce FRP products of varying sizes and specifications. The equipment can be designed with either a three-beam, four-column structure or a frame structure, depending on the customer’s process requirements. Commonly available capacities include 630, 800, 1000, and 1200 tons.

Features of the Hydraulic Press for Molding FRP/GRP Water Tank Panels

1. The machine body utilizes a computer-optimized design, featuring an all-steel four-column structure. It undergoes furnace tempering or vibration aging for excellent precision retention.

2. The slide utilizes a four-column guide rail, which offers excellent adjustment precision, strong rigidity, and excellent precision retention.

3. New cylinder sealing elements provide enhanced reliability and long service life.

4. The slide of the hydraulic press for molding FRP water tanks features fast operating speeds and high efficiency.

5. The hydraulic control utilizes an integrated cartridge valve system, offering reliable operation, high flow, minimal internal leakage, and a long service life. This highly integrated system reduces the need for connecting pipes and leak points.

6. The slide’s operating pressure, as well as its no-load rapid downward movement and slow forward movement travel ranges, can be adjusted to meet process requirements.

7. The control panel allows for both fixed-stroke and fixed-pressure molding processes, with features such as pressure-holding and time delay.

8. The system can be configured with an in-mold core-pulling control system and a preset in-mold ejection control system. It can perform a series of actions, including rapid descent, staged compression, staged deflation, operation, pressure holding, slow mold opening, rapid return, slow mold release, rapid ejection, ejection pause, and rapid return. Temperature can be controlled at multiple points.

9. The FRP/GRP machine for panel tank features an independent electrical control system, ensuring reliable operation, precise movement, and easy maintenance.

Applications of FRP/GRP Water Tank Panel Pressing Machine

- Municipal and Civil Water Supply: Produces modular fiberglass tank panels for residential buildings, office buildings, hotels, and other structures. These panels can be assembled into large rooftop water tanks or underground water storage tanks, providing corrosion resistance and ensuring the quality of the water.

- Fire Water Storage Systems: Manufactures specialized fire water tank panels suitable for fire water storage tanks in public facilities such as factories, schools, shopping malls, and hospitals, ensuring long-term structural strength and water quality.

- Industrial Water Storage and Chemical Vessels: Produces acid- and alkali-resistant, corrosion-resistant panels for industrial tanks, such as chemical plant raw material storage tanks and cooling circulating water tanks, suitable for high humidity and high salt environments.

- Food and Pharmaceutical Industries: Presses food-grade and medical-grade panels for assembly into purified water tanks, beverage production tanks, and pharmaceutical liquid storage tanks, meeting hygiene standards.

- Desalination and Coastal Facilities: Suitable for producing water storage panels for desalination projects or coastal areas, offering salt spray and UV resistance and a long service life. Agriculture and Environmental Protection: Producing panels for agricultural irrigation reservoirs, aquaculture tanks, and wastewater treatment tanks, facilitating large-scale assembly and maintenance.

- Customized Large Tank Panels: By changing molds and adjusting process parameters, specialized panels with varying thicknesses, sizes, and textures can be produced to meet individual project needs.

Technical Parameters of FRP/GRP Water Tank Plate Forming Hydraulic Press

| Model/Technical Parameters | 630T | 800T | |

| Nominal Pressure (KN) | 6300 | 8000 | |

| System Pressure (MPa) | 25 | 25 | |

| Slider Stroke (mm) | 700 | 800 | |

| Maximum Opening Height (mm) | 1200 | 1300 | |

|

Effective Area of Workbench (mm*mm) |

Left-Right (distance between columns) | 1500 | 1800 |

| Front-back (front to back of workbench) | 1400 | 1500 | |

| Downward Stroke Speed (mm/s) | 180 | 180 | |

| Pressing Speed (mm/s) | 5-15 | 5-15 | |

| Return Stroke Speed (mm/s) | 150 | 150 | |

| Lower Cylinder (T) | 120 | 150 | |

| Lower Cylinder Stroke (mm) | 200 | 200 | |

| Motor Power (kW) | 22*2 | 22*2 | |

| Workbench Height (mm) | 850 | 900 | |

Detailed Introduction of FRP/GRP Water Tank Panel Pressing Machine

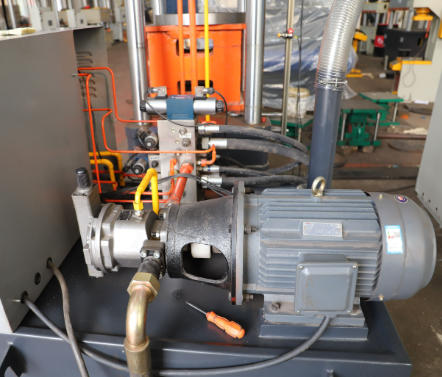

1) Hydraulic System

The hydraulic system is located on the right side of the press. It utilizes an integrated cartridge system, ensuring flexible movement, reliable operation, and excellent sealing performance. The hydraulic pump includes a reservoir, high-pressure pump, motor, cartridge valve, and other components.

2) Piston Rod

The piston rod is made of 45 steel using medium-frequency hardening, deepening the material by 2-3 mm, achieving a surface hardness of 55. This effectively reduces damage to the sealing ring and resists scratching.

3) Cartridge Valve System

Cartridge valves are integrated into the system, reducing leak points and ensuring reliable operation with a long service life.

4) Combination Gasket

All oil joints are sealed with a combination of gaskets, using rubber on the inside and copper on the outside, custom-made by the manufacturer. Compared to irons used by other manufacturers, these advantages are:

(1) Copper’s high ductility ensures a tight bond.

(2) Copper effectively protects the rubber from damage during high-pressure washing.

5) Core Electrical

Relay control (PLC optional) is employed. This allows for electro-hydraulic control, inching, manual, and semi-automatic operation.

6) Hydraulic Station Layout

Compared to plug-in oil pumps, we utilize an external, horizontal location to reduce the heat generated when pumping oil. The oil rises slowly, maintaining a controlled temperature of approximately 55°C. This allows hydraulic components to operate at a tolerable temperature, thereby extending the service life of the composite material molding machine.

7) Hydraulic Oil Tank

Shot blasting combines three innovative processes: high-pressure vacuum and dough removal. After equipment commissioning, the tank is opened again, and hydraulic oil flows under high pressure into the main tank, cleaning all components twice.

Related Products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.