Professional Composite Hydraulic Press Manufacturer

As a leading composite hydraulic press manufacturer in China, PDH focuses on delivering high-performance composite molding press solutions tailored to customer needs. Our composite presses are designed for precision, stability, and durability—ideal for producing SMC, BMC, GMT, and other composite parts. With advanced control systems and competitive pricing, we provide reliable equipment to support your efficient, high-quality production. Looking for a cost-effective composite press? Contact us today!

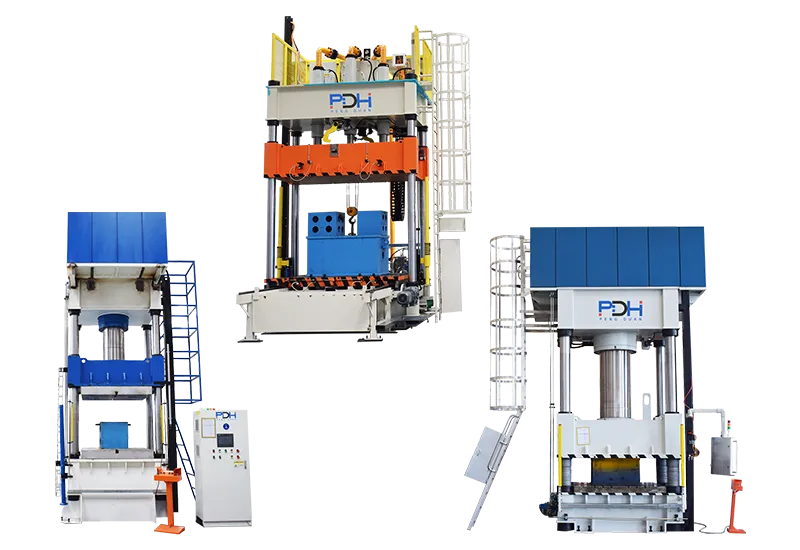

Hydraulic Presses

Contact Us

630T Automotive Interior Press

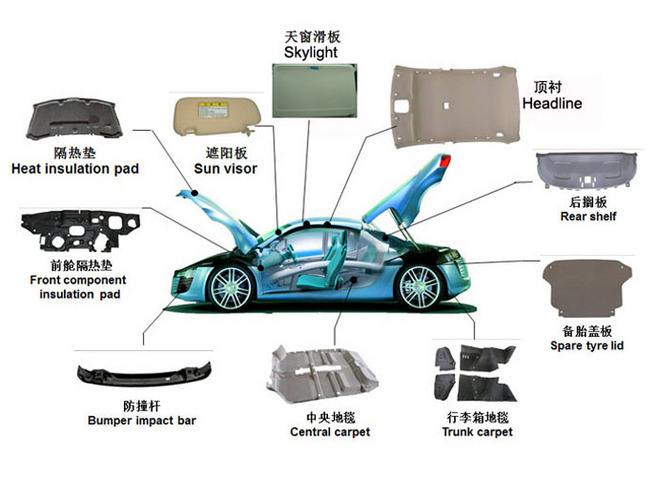

Automotive interior molding presses are specialized hydraulic presses used for hot-pressing and compression molding automotive interior components, such as roofs, door panels, instrument panels, rear fenders, carpets, sound insulation, and trunk mats. They utilize a hydraulic system to provide stable and powerful pressure, heating the mold to shape and press raw materials such as sheet materials, fiber mats, and thermoplastic/thermoset composites, resulting in automotive interior products with precise dimensions, smooth surfaces, and strong structures.

Description

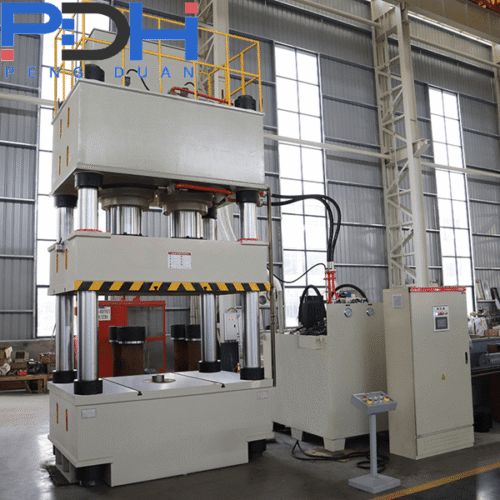

The automotive interior press is designed specifically for the automotive interior parts industry. It is suitable for pressing, trimming, and blanking automotive interior parts. It features a large work surface, high speed, and uniform product pressure.

PDH‘s automotive interior hydraulic press utilizes PLC automatic control for easy operation. The operating pressure and stroke can be adjusted within specified ranges to meet process requirements. It utilizes an advanced cartridge valve integration system, providing high flow rates, stable operation, and pressure overload protection. A safety lock mechanism is installed on the upper slider limit, and a photoelectric safety device is installed on the front of the work table to ensure personal safety during operation, mold changes, and maintenance.

Features of the Car Interior Parts Molding Machine:

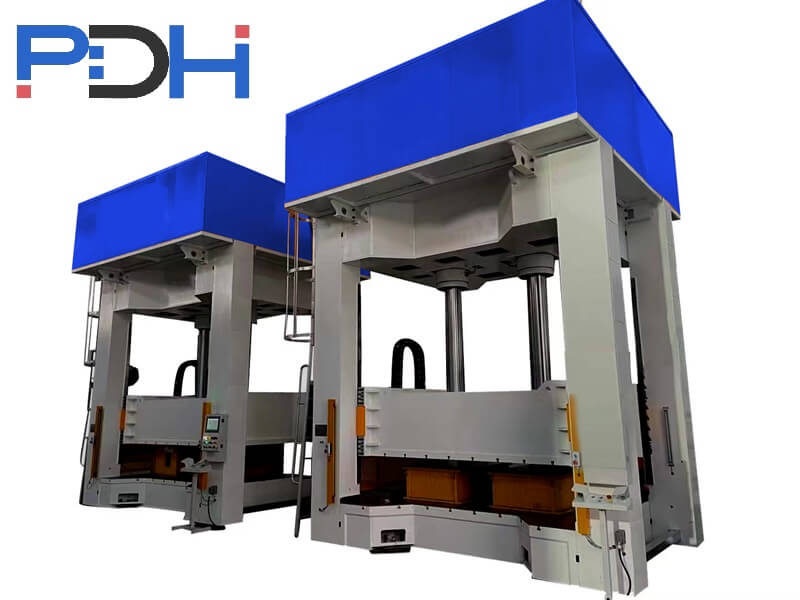

- The machine has an enlarged and widened design with plenty of space around it for easy operation.

- The hydraulic system uses integrated cartridge valves for flexible, reliable, and leak-free operation.

- The electrical system features a Mitsubishi PLC and touchscreen control system from Japan for simple use and dependable performance.

- The hydraulic press includes a safety circuit and a locking device at the slide’s TDC (top dead center) position for greater safety.

- The multi-cylinder design provides even force distribution across the large worktable.

Automotive Interior Press Structure

- Main Unit: Four-column or frame-type

- Hydraulic System: Hydraulic cylinder, oil pump, and valve block provide pressing power

- Electronic Control System: PLC or touchscreen control, supporting multiple pressure, speed, and time settings

- Heating System: Electric heating or thermal oil heating to ensure stable mold temperature

- Auxiliary Equipment: Automatic loading, robotic removal, cooling table, and trimming equipment

Advantages of Automotive Interior Hydraulic Presses

- One-shot molding. Reduces post-processing steps and improves production efficiency.

- High product consistency. Ensures dimensional accuracy and aesthetics of automotive interior parts.

- Compatible with a variety of materials. Adapts to the trend of lightweight and environmentally friendly vehicles.

- Multiple uses for one machine. Simply change the mold to process different types of automotive parts.

Main Applications of Automotive Interior Presses

- Headliner molding: For example, hot-press molding of fiber felt/cloth-based headliners.

- Door panel and instrument panel molding: For compression molding of multi-layer composite structures.

- Carpet and sound insulation molding: For compression molding of thermoplastic materials such as PET and PP.

- Truck liner/panel molding: For mass production of lightweight, wear-resistant interior components.

Technical Parameters of Car Interior Molding Machine

| Project | Unit | 400T | 500T | 630t | 800T | 1000T | 1250t | 1600t |

| Liquid Pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Slider Stroke | mm | 800 | 900 | 900 | 1000 | 900 | 900 | 1000 |

| Maximum Opening Height | mm | 1250 | 1500 | 1500 | 1800 | 1600 | 1600 | 1800 |

| Worktable Effective Area | mm*mm | 1260*1160 | 1400*1400 | 1600*1600 | 1500*1500 | 1500*1500 | 1800*1600 | 1600*1600 |

| Idle Stroke Lowering Speed | mm/s | 100 | 150 | 150 | 180 | 180 | 160 | 180 |

| Pressing Speed | mm/s | 5-11 | 10-18 | 9-18 | 9-18 | 10-18 | 10-18 | 6-14 |

| Returning Speed | mm/s | 100 | 120 | 150 | 180 | 220 | 200 | 220 |

| Motor Power | KW | 45 | 45 | 45 | 37*2 | 37*2 | 37*2 | 37*2 |

| Ejector Force | KN | 630 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 |

| Ejector Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 350 |

As a professional hydraulic press manufacturer, PDH offers 315-ton, 500-ton, 630-ton, 800-ton, and 1000-ton hydraulic presses for automotive interior parts. We also offer custom services. Please contact us if you require any.

Related Products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Related products

Talk to Our Expert About Your Needs

PDH is a design, development, production and sales of an integrated company. We can give you professional advise.